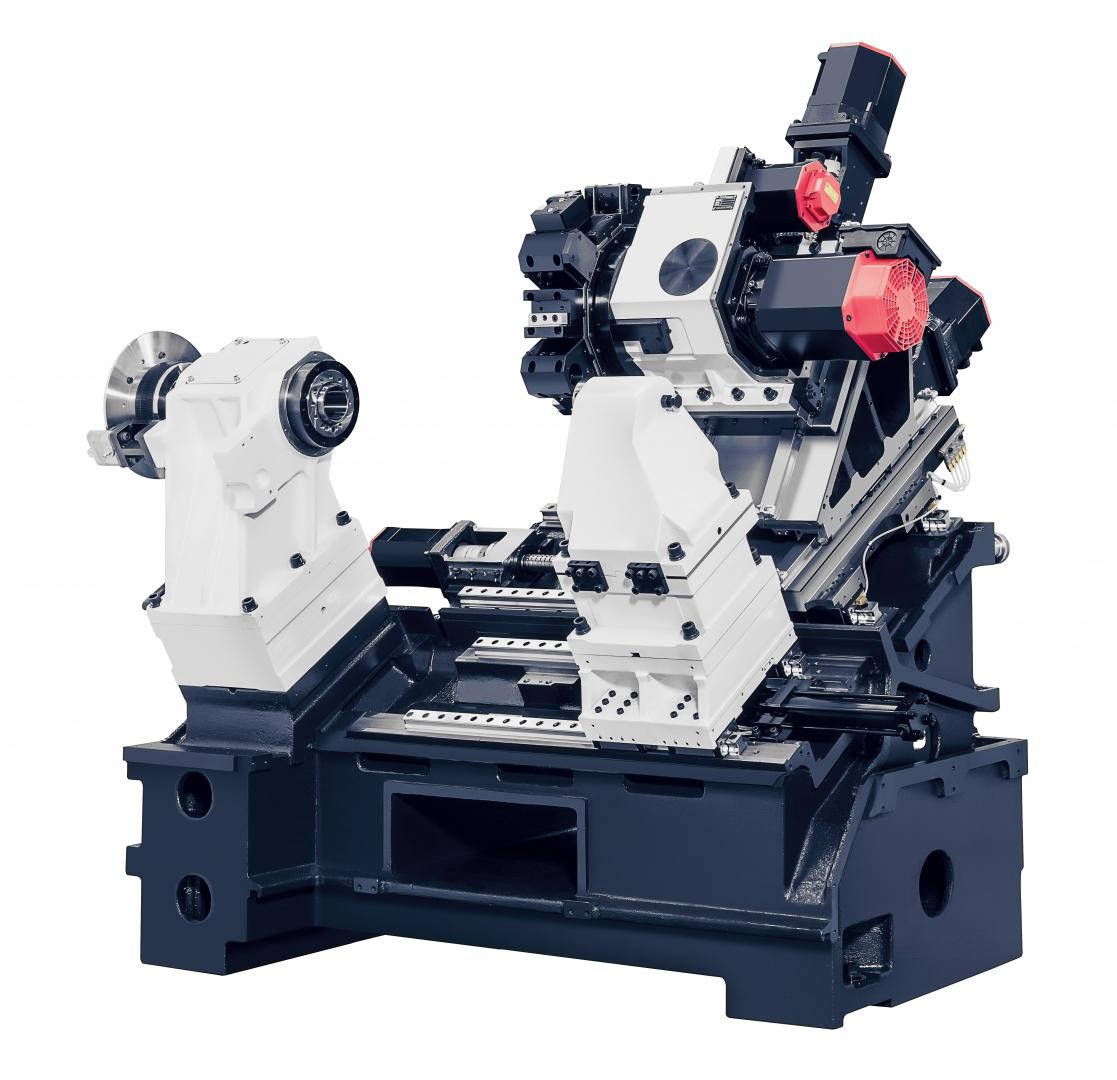

CUTEX-180

6″-8″ Chuck Horizontal Turning Center

New Standard For Compact Lathe

The main spindle and turn mill specifications, and its user convenience are enhanced compared to the existing model. The optional Y-axis has a total stroke of 110mm maximum which is the largest in class, maximizing its machining performance and productivity.

Category Horizontal CNC Turning Centers

Tags Driven tools, Fanuc 0i, Linear guideway, Slanted bed, Sub spindle, Y-Axis

6″-8″ Chuck Horizontal Turning Center

Optimised productivity characterises the new CUTEX-180 compact lathe. the programmable tail stock reduces the cutting time of the workpiece by more than 70 percent. Optionally, the machine can be fitted with a sub spindle which makes it possible to machine the front and the back of the workpiece.

The 12-position turret with 24 indexable stations which, when double tool holders are used, can be equipped with the same number of tools, permits shorter process times, even during complex machining tasks. In addition to this, the Y axis model has the biggest traverse path of its class, with further positive impacts on productivity. An extremely stable machine bed, linear rolling guideways on all axes, and generously proportioned spindle bearings ensure the efficient production of high quality output.

Main features

- Highly rigid roller LM guide to every axis

- Upgraded main spindle motor

- The highest turn-mill motor power in this class

- Extended max bar diameter

- Possible to apply 24 tools to the index turret

Enhanced User Convenience

- Lighter door to support operator

- Structure to prevent chip accumulation in the bottom

- 90 degrees rotating operator panel

- Optional software for user convenience (operating and machining)

Easy Maintenance

- Coolant tank placed at the front to be removed for maintenance

- Coolant level sensor standard

- Easy access cover for maintenance

- Use of external coolant block prevents the leakage of turret inside

Specifications

Mechanical specifications

| Swing Over Bed [mm] | Ø545 |

|---|---|

| Max. Cutting Length [mm] | 328 |

| Spindle Power [kW] | 15 / 11 |

| Spindle Speed (A / B) [rpm] | 6000 / 4,500 |

| Number of Tool Stations (MC) [Amount] | 12 (24 Pos. index) |

| Rapid Speed [m/min] | 36 / 36 / 10 |

| Turn Mill Motor Power [kW] | 5.5 / 3.7 |

| Turning Length, Max. (L-Version) [mm] | 328 (528) |

| NC System | Fanuc 0i-TF |

Details

Software

Processing software

- L-HTLDHwacheon Spindle Displacement Control System

Learn more about Hwacheon processing software

Related products

- 5-AXIS CNC Machining Centers (Multi Tasking)

D2-5AX

- Horizontal CNC Machining Centers

H6

- Vertical CNC Machining Centers

L1 / L2

- Vertical CNC Machining Centers

SIRIUS-UL+