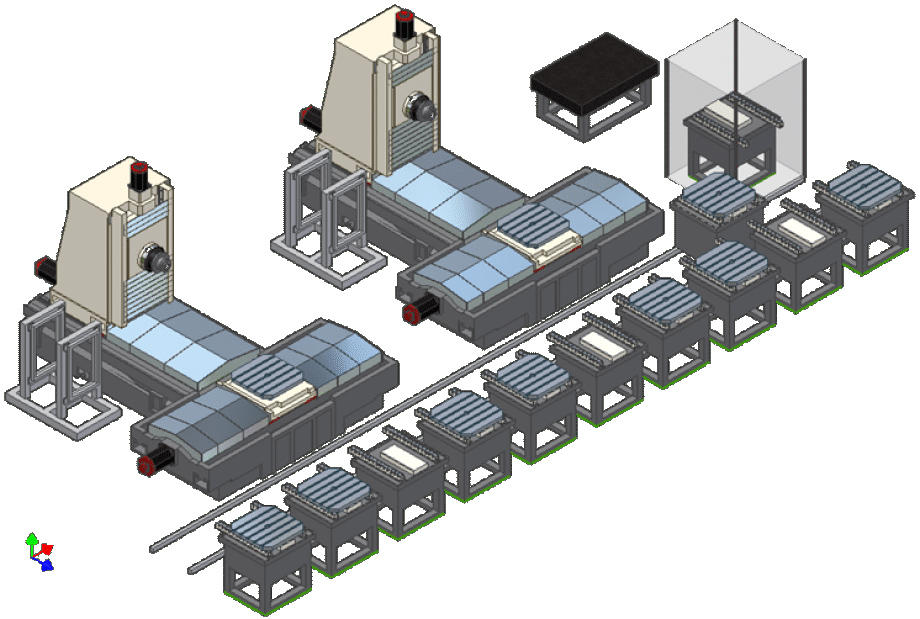

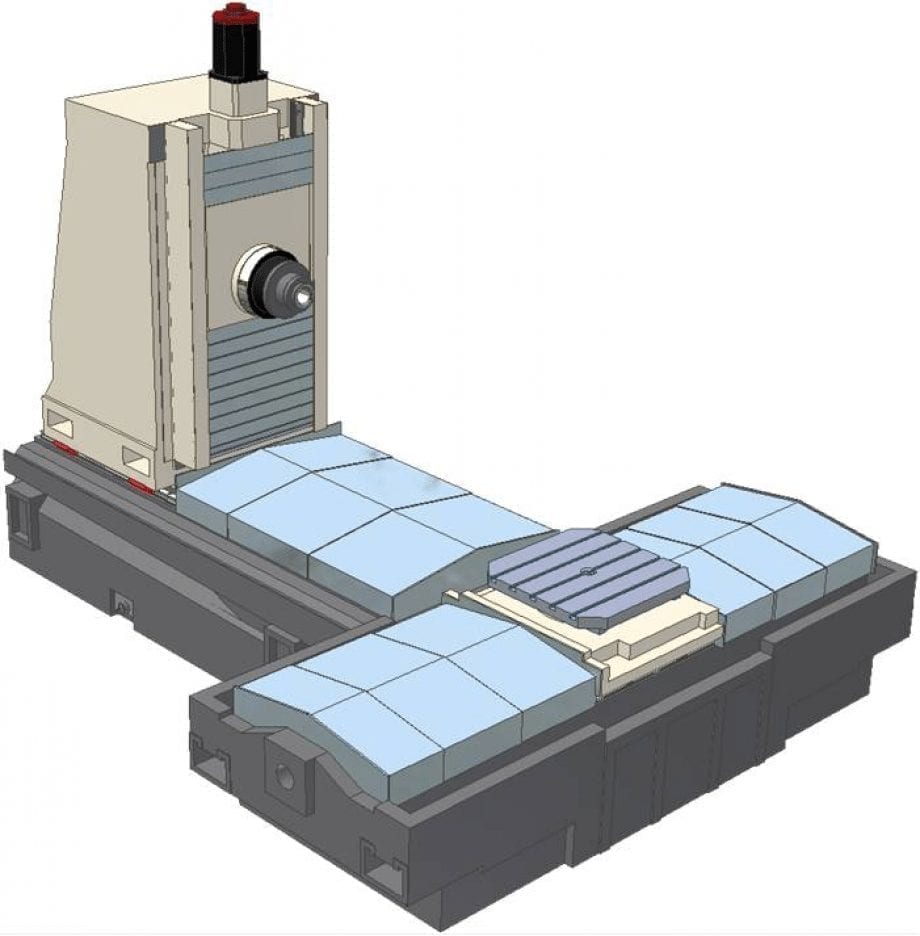

AF-16

LARGE SIZE HORIZONTAL MACHINING CENTER

High Productivity For Parts & Components

The AF-16 is a excellent solution for producing various kinds of parts which require both, high rigidity and productivity. The high torque spindle is either equipped with a direct drive motor spindle or a strong gear system. Hwacheon’s unique Oil-Jet cooling system ensures stable cutting and high quality even during long machining times. Additionally, the stable frame structure designed with FEM analysis will enhance the quality and accuracy of your products.

The AF-16 with Hwacheon’s unique software enables users to get high efficiency, productivity, stability and convenience at the same time. High precision worm gear and rotary encoders at B-axis will maintain high accuracy. Furthermore, users can fix rotating axis by using hydraulic force for rough face cutting and drilling on fixed angle, it will ensure stability and precision.

High Rigid & Large Horizontal Machining Center

- High rigid LM guide in all axes

- Stroke (X/Y/Z): 2,600/1,600/1,500 mm

- Max. work size: Ø2,500 x 1,800 mm

- Max loading weight : 15,000 kg (2-APC: 7,000kg)

Powerful Spindle

- High Speed: BT-50/3,000 rpm (Std), 8,000/12,000 rpm (Optional)

- High Power Motor: 26/22 kW

- Spindle lub. and cooling system: Oil-Jet lubrication

Various Functions

- Hwacheon’s unique software technology: HAI, HECC, HTLD, OPTIMA, HTDC (Std.)

- B-axis control by 0.001° ensures machine precision (Std.)

- Through Spindle Coolant (Opt.): 30/70 bar

Reliable Accuracy

- Linear Scale for all axes (Std.)

- Ball Screw Core Cooling (Std.)

Mechanical specifications

| Stroke (X / Y / Z) [mm] | 2600 (3000) / 1600 / 1500 |

|---|---|

| Stroke W-Axis [mm] | 300 |

| B-axis Rotation Angle | 360° |

| Table Loading Capacity [kg] | 15000 |

| Max. Workpiece Size (D x L) [mm] | 2500 x 1800 |

| Max. Spindle Speed [rpm] | 3000 / 8000 / 12000 |

| Spindle Motor Power (opt.) kW | 26 / 22 (30/25) |

| Tool Storage Capacity (opt.) [Amount] | 60 (120/180) |

| Controller | Fanuc 31i-B |

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Double Column Vertical CNC Machining Centers

SIRIUS-1750

- Vertical CNC Machining Centers

VESTA-2000

- Vertical CNC Machining Centers

VESTA-1000+

- Vertical CNC Machining Centers

VESTA-1050B