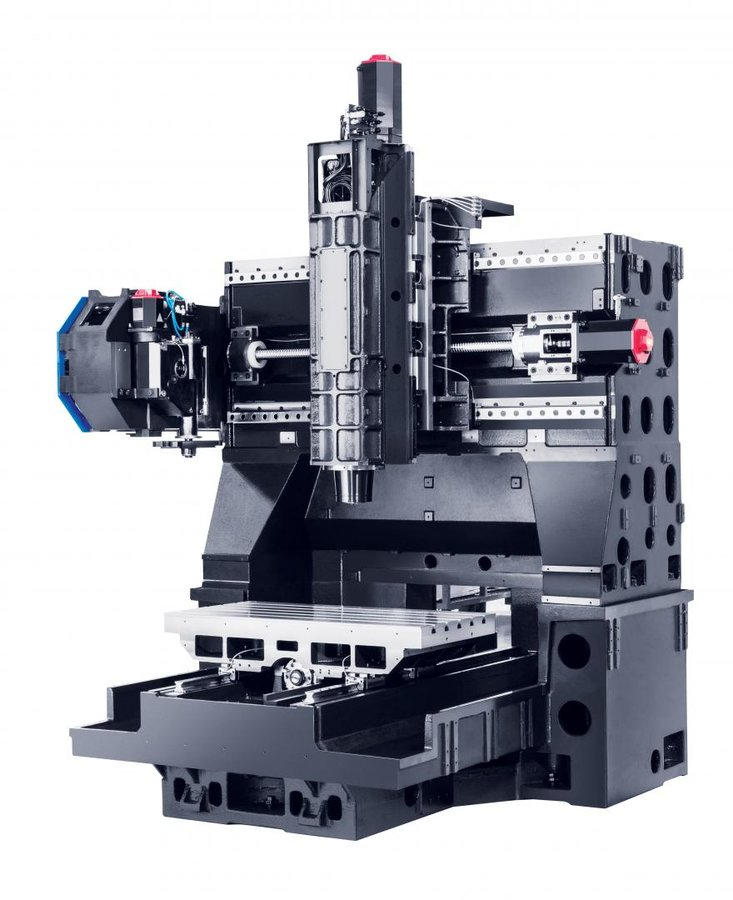

SIRIUS-UL+

HIGH SPEED VERTICAL MACHINING CENTER

600MM Y-Axis For Mold & Die Applications

SIRIUS-UL+ “New” is a vertical mold & die center whose performance provides your company a total one stop production solution, from tool selection to final product.

- Motor-integrated spindle : 20,000 or 32,000 rpm

- Oil-jet (Hi-Yun premium oil) lubricated bearing

- Fast, stable roller linear guide system

- Bridge gate structure guarantees rigid machine frame

- FEM analysis frame design

Each SIRIUS-UL+ “New“machining center is manufactured to perfection with Hwacheon’s workmanship. Quality is recognized in the industry and it guarantees to give you a perfect result every time.

The high performance spindle with Hwacheon’s Oil-jet Cooling technology ensures consistent quality result after hours and hours of operation, while the machine’s Optimal Machining system gives you a total production solution, from tool selection to final product.

SIRIUS-UL+ “New” is designed using 3D simulations and the FEM analysis to achieve structural rigidity which translate to quality product results; while the Hwacheon-designed machining software components enhance work efficiency. The SIRIUS-UM is configurable with many different options to suit your application requirements.

High-performance spindle design

Hwacheon spindle integrates the motor to limit vibration, noise and any power loss at high speed. Oil is injected directly onto the spindle bearing for most effective cooling, the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, the spindle constantly monitors for possible thermal displacement and makes necessary adjustment in real time.

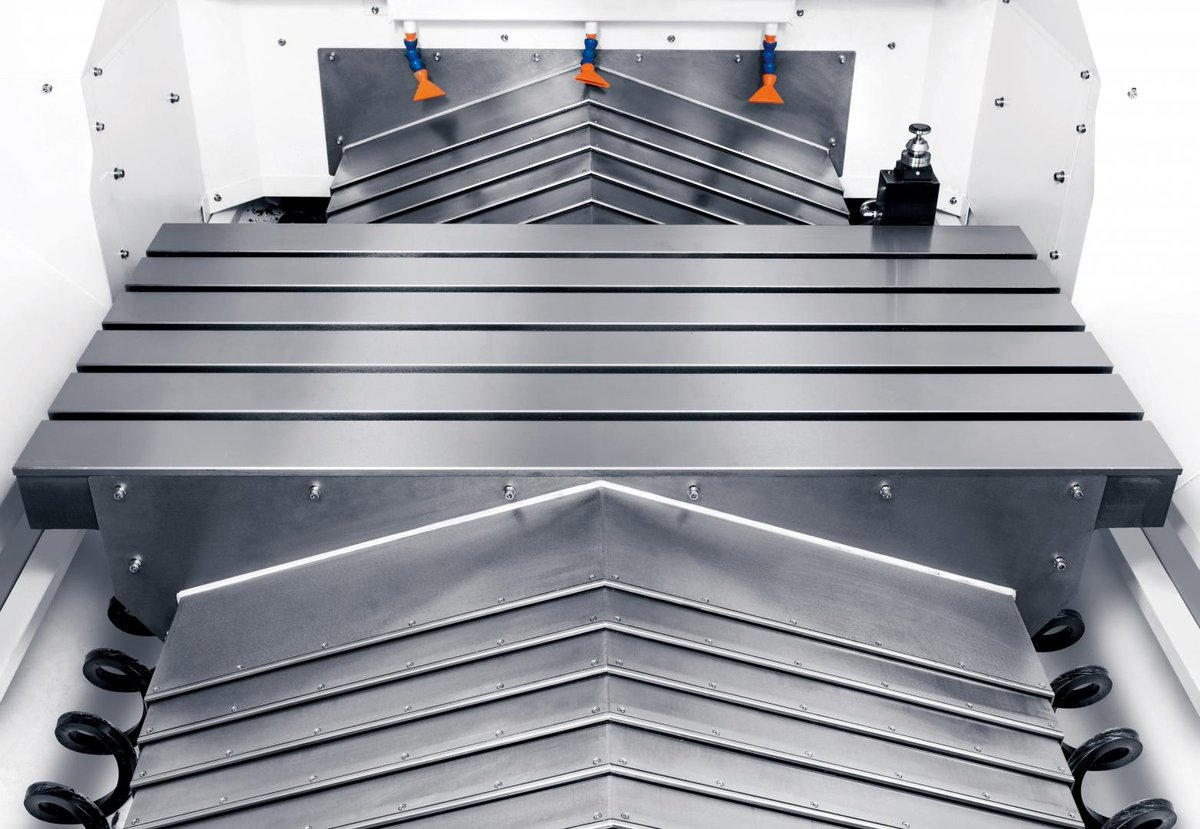

High-precision feed drive

SIRIUS-UL+ “New” provides rigid feed performance by using 6-block LM guide at Z-axis. The servo motor is coupled directly to the drive; and while the tensile preload ball screws provide smooth operation, the roller linear guide allows for rapid feed.

Mechanical specifications

| Stroke (X / Y / Z) [mm] | 1050 / 600 / 550 |

|---|---|

| Rapid Speed (X / Y / Z) [m/min] | 36 / 36 / 36 |

| Table Size [mm] | 1200 x 600 |

| Table Loading Capacity [kg] | 800 |

| Spindle Speed (optional) [rpm] | 20000 / 14000 |

| Spindle Motor [kVA] | 22 / 18,5 |

| Type of Spindle Taper Hole | BT-40 (Option: BBT-40, CAT-40) |

| Tool Storage Capacity [Amount] | 30 |

| Floor Space (Length X Width) [mm] | 3537 x 2742 |

| NC System | Fanuc 31i-B |

Processing samples

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Double Column Vertical CNC Machining Centers

SIRIUS-2500

- Vertical CNC Machining Centers

VESTA-2000

- Vertical CNC Machining Centers

VESTA-1000+

- Vertical CNC Machining Centers

VESTA-1300B