VESTA-850B

BOX WAY VERTICAL MACHINING CENTER

High Precision Heavy Duty Machining

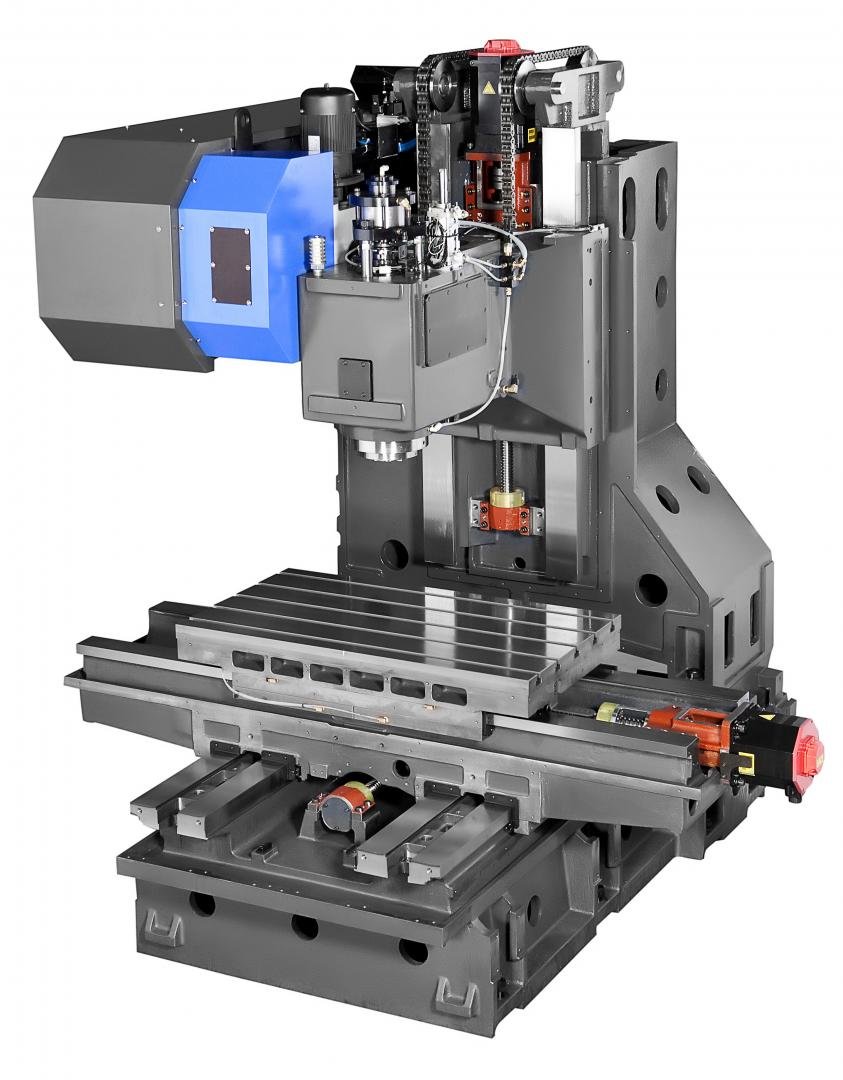

VESTA-850B designed in highly tough, highly rigid box way design on all axes for ultimate precision and stability . These machines can be configured with a wide choice of options to satisfy your production needs.

- 8,000 rpm or 6,000 rpm high-speed spindles

- Travel (X/Y/Z): 850/600/600 mm

- Gear-driven high-torque spindle: 2-speed shifting

- Box way design for all axes

In heavy duty cutting, stability is the key

Everything about VESTA-850B is detail. These machining centers don’t miss even the smallest detail to ensure top performance. Built with Hwacheon’s advanced technology and craftsmanship, VESTA-850B is the class-leading vertical machining center that will guarantee to give you the quality you seek for your manufacture requirements. The 850B’s feed drive employs all-axis box way design for precision and performance; while the structure is 3D FEM analyzed to make it tough yet efficient.

Built-Out Spindle

Hwacheon’s spindles are the best and built by Hwacheon. The high-performance spindle provides stability and precision at high speed; the temperature around the spindle assembly is efficiently regulated with Hwacheon’s unique oil-jet lubrication system, to limit heat distortion. The spindle gear system is providing highest torque.

Spindle Cooling System

The motor bearings are lubricated with the semi-permanent grease. The coolant travels around the motor housing jacket.

Air-Oil Cooling System

Air-oil cooling technology, combined with conventional jacket cooling, limits heat distortion even after the machine is used for prolonged operation.

Gear Driven Spindle

The 2-speed auto-shifting gear spindle delivers high torque cutting performance at extra low speeds; while providing excellent performance at high speeds.

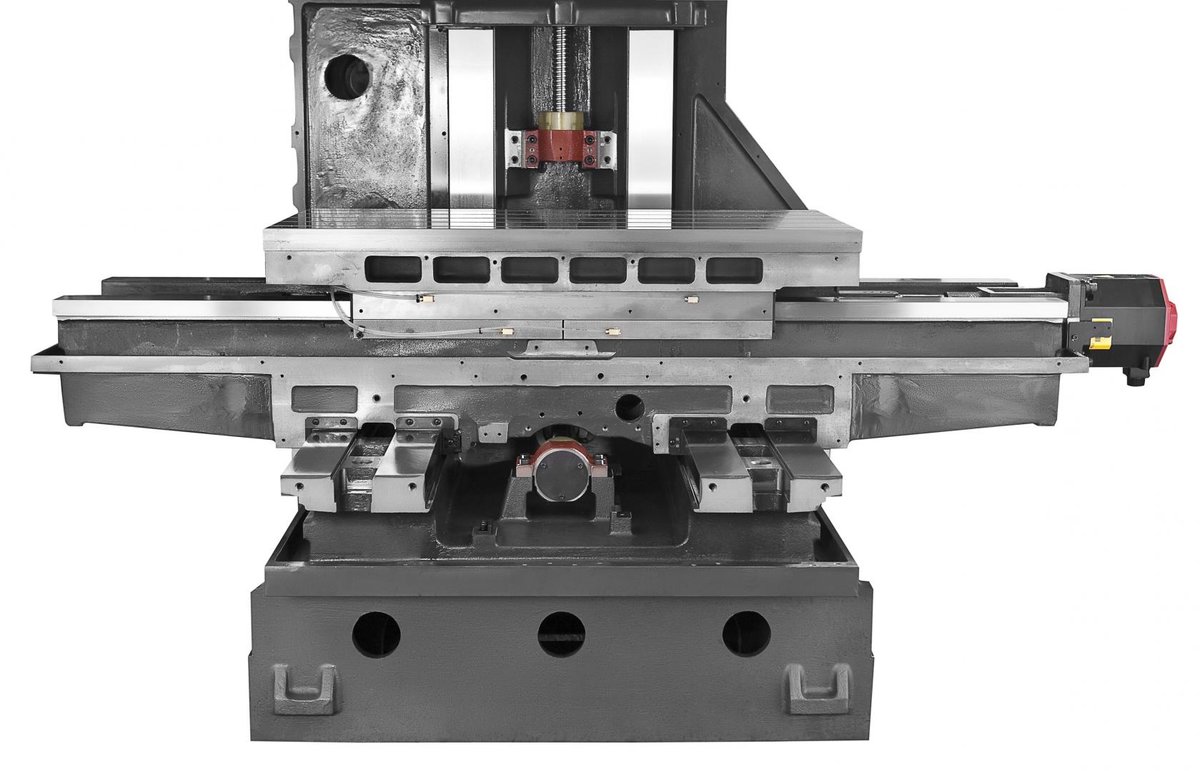

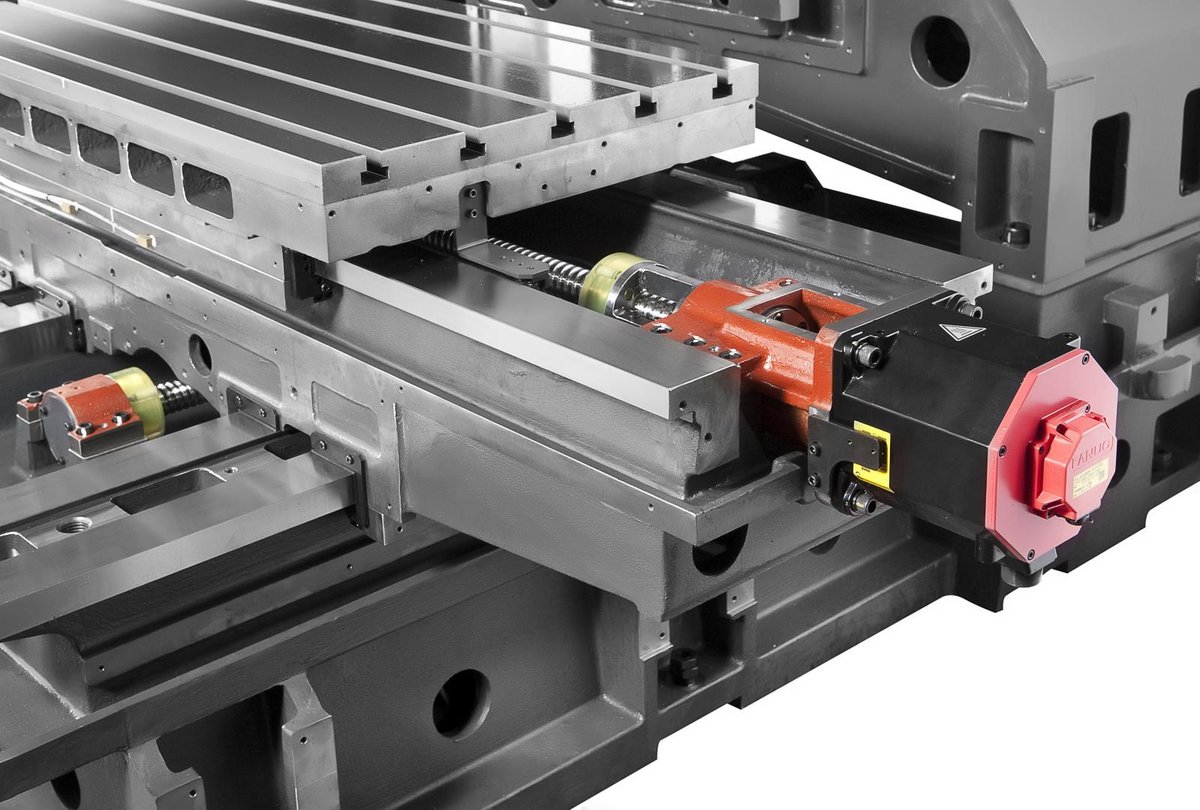

4-Guide Box Way

To limit friction and to increase accurate table feed, the 4-guide box way has been incorporated to the axes. The Y-axis slide way has been widened to enhance the bearing capacity and decrease the area of friction.

Fast Chip Removal Performance

The chip removal system in VESTA series of machining centers are designed with a wide-angle sliding cover and the chip flushing nozzles on each side of the table; and the coil conveyor in front removes the chips quickly and effectively, to make your work more efficient.

Mechanical specifications

| Stroke (X / Y / Z) [mm] | 850 / 600 / 600 |

|---|---|

| Feedrate Rapid Speed (X / Y / Z) [m/min] | 24 / 24 / 18 |

| Table Size (Width x Length) [mm] | 1,050 x 600 |

| Table Loading Capacity [kg] | 800 |

| Max. Spindle Speed [rpm] | 8,000 (6,000) |

| Spindle Motor Power [kW] | 11 / 7.5 (18.5 / 15) |

| Type of Tool Shank | BT-40 (Opt. CAT-40) / BT-50 (Opt. CAT-50) |

| Tool Storage Capacity [Amount] | 24 (Opt. 30) |

| Floor Space (Length X Width) [mm] | 3,640 X 2,185 |

| NC System | Fanuc 0i-MF |

Processing samples

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Double Column Vertical CNC Machining Centers

SIRIUS-1750

- Vertical CNC Machining Centers

SIRIUS-UX

- Vertical CNC Machining Centers

VESTA-500T

- Vertical CNC Machining Centers

VESTA-1050B