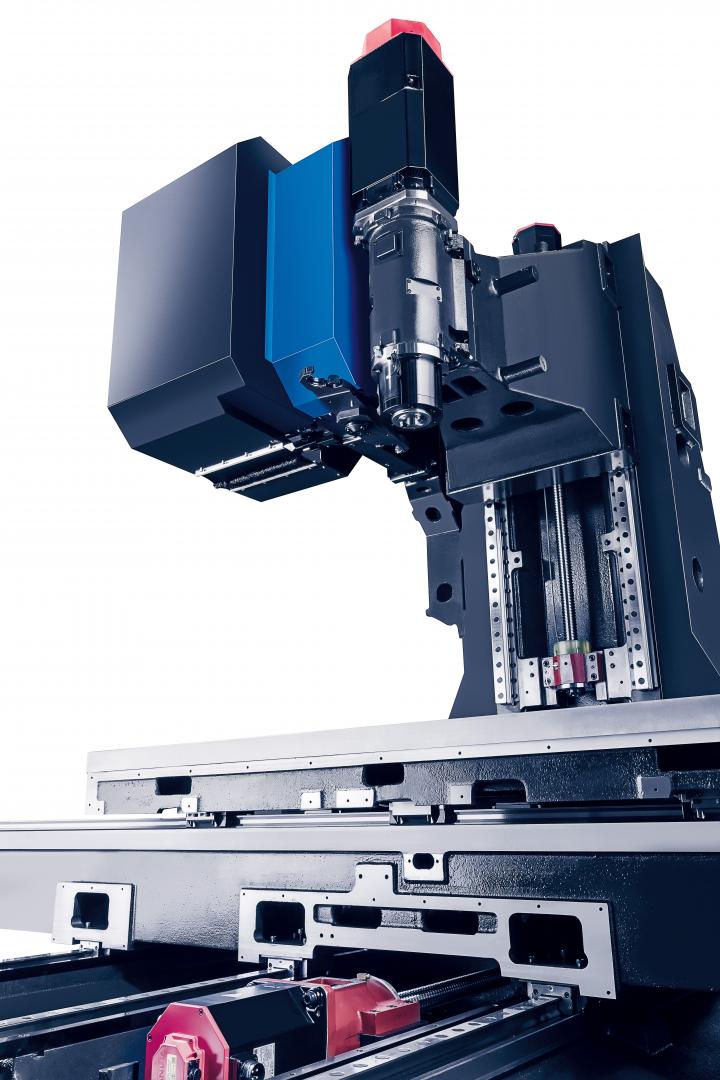

VESTA-2000

850MM Y-AXIS VERTICAL MACHINING CENTER

Software Optimized For Enhanced Productivity

VESTA-2000 for powerful cutting operations based on its rigid structure. It is equipped with Hwacheon’s proprietary technologies such as productivity enhancement software (HECC, HTLD and OPTIMA) and precision enhancement software (HTDC and HAI) and provides differentiated quality different from existing machining center for parts.

Category Vertical CNC Machining Centers

Tags 3 axis, Cross table, Fanuc 0i, Linear guideway

Upgrades for Enhanced Machining Performance

- High rigid roller LM guide for every axis

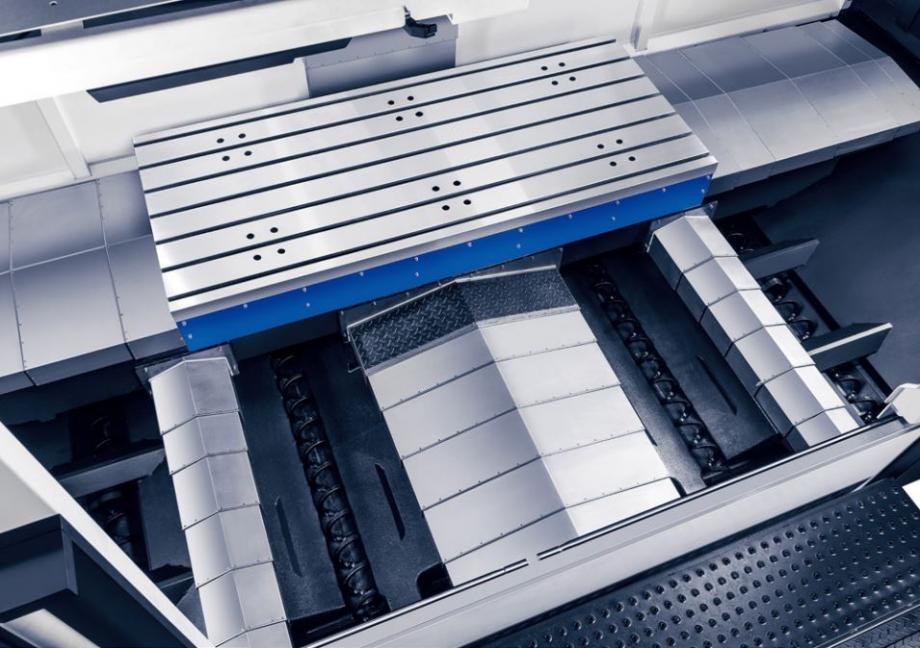

- 4 Coil conveyors to enhance chip discharge performance

- The table wide enough to mount multiple workpieces

- Various direct-coupled main spindle specifications that meet machining purposes

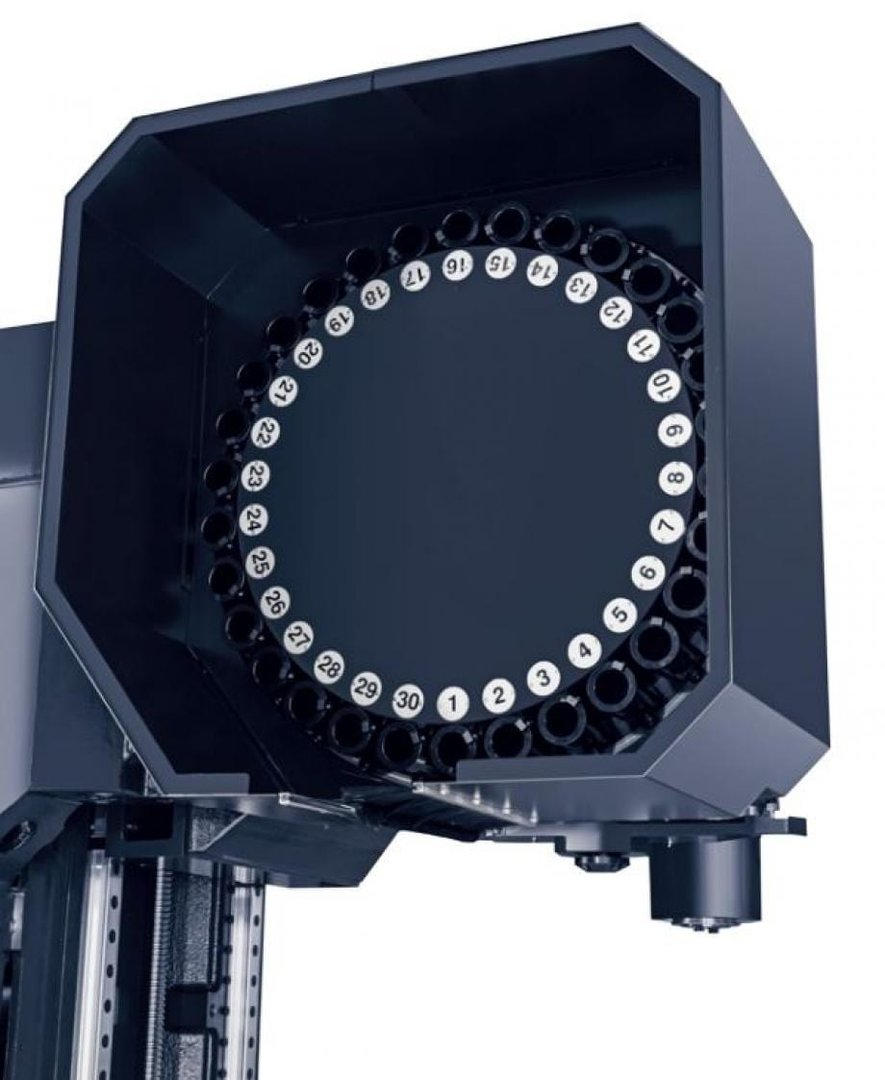

- The servo type ATC (BT-40) to enhance the tool change time

- Hwacheon’s proprietary software

Enhanced User Convenience

- The tempered safety glass ensures machining visibility

- The step integrated coolant tank ensures the front table accessibility

- Eco-friendly oil water separation structure

Easy Maintenance

- Peripherals requiring maintenance are gathered in one place

- Easy lubrication points

Specifications

In action

Samples

Software

Specifications

Mechanical specifications

| Stroke (X / Y / Z) [mm] | 2000 / 850 / 800 |

|---|---|

| Table size [mm] | 2000 / 850 |

| Spindle Speed [rpm] | 12000 |

| Spindle Power [kW] | 18,5 / 11 |

| Weight [kg] | 14,200 |

In action

Samples

Processing samples

Software

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Vertical CNC Machining Centers

HiT-400 (L)

- Double Column Vertical CNC Machining Centers

SIRIUS-2500

- Double Column Vertical CNC Machining Centers

SIRIUS-1350

- Vertical CNC Machining Centers

VESTA-650T