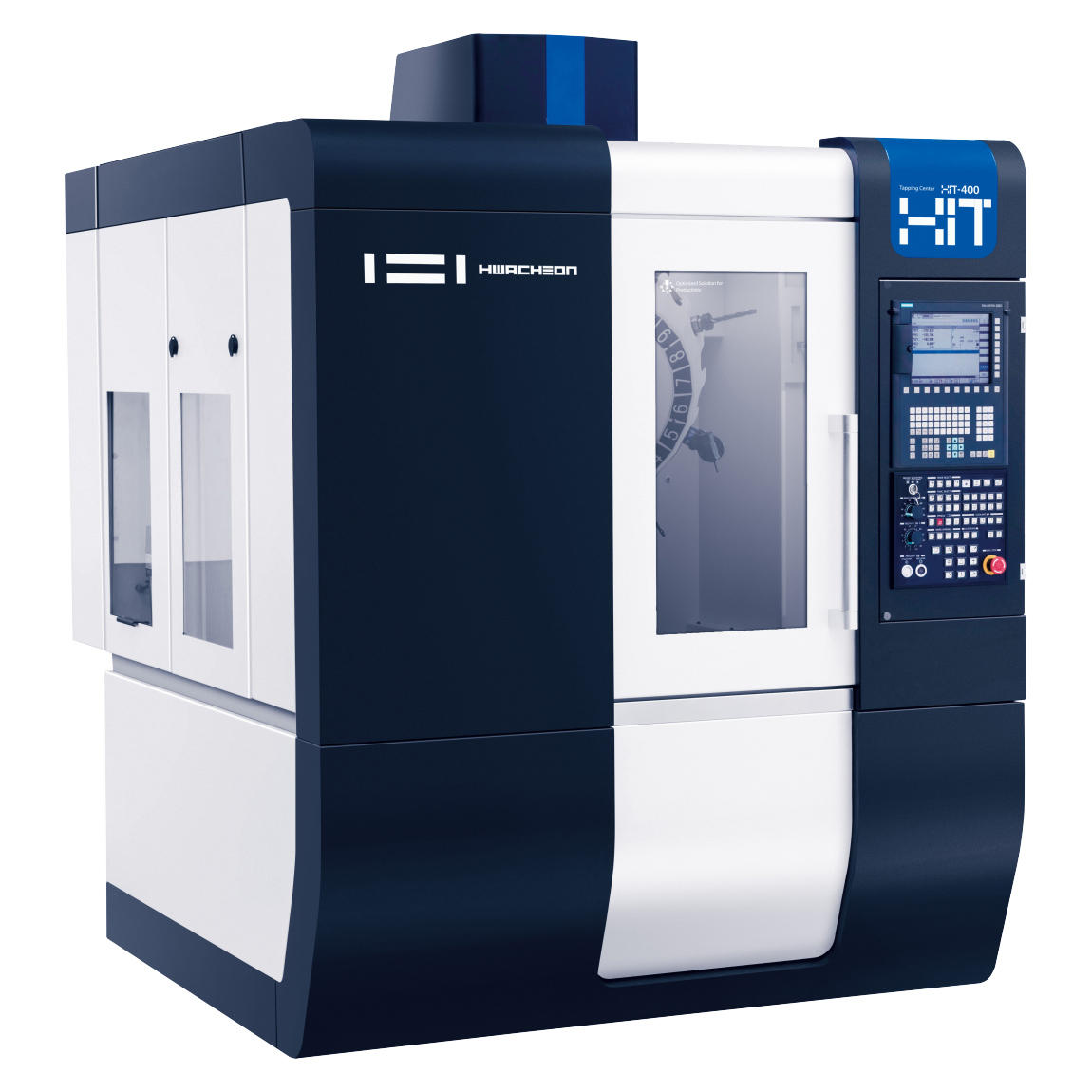

HiT-400 (L)

HIGH SPEED TAPPING & DRILL CENTER

A stable machining process for tasks like rigid tapping, drilling and cutting are ensured by strong drives and a heavy machine body. Rapid speed rates up to 60 m/min and a chip-to-chip time of only 1.6 seconds boosts your productivity and profit. The dual table enables a batch processing where the machine operator or a robot picks up the finished workpiece.

Compact Highspeed Machining Center (Tapping-Center)

The innovative HiT-400 and HiT-400L machining centres set new standards in the efficient production of medium to large batches. A high-speed spindle with a direct spindle connection enables high productivity and stable tapping, even for small taps.

Rapid tool changing and high traverse speeds of up to 60 m/min make the machining centre a real hit in terms of efficiency.

Stable guideways and ball screws as well as minimised thermal displacement by means of ceramic bearings ensure precision during machining despite increased productivity.

Table in two different sizes

- HiT-400: 600 x 400 mm

- HiT-400L: 800 x 400 mm

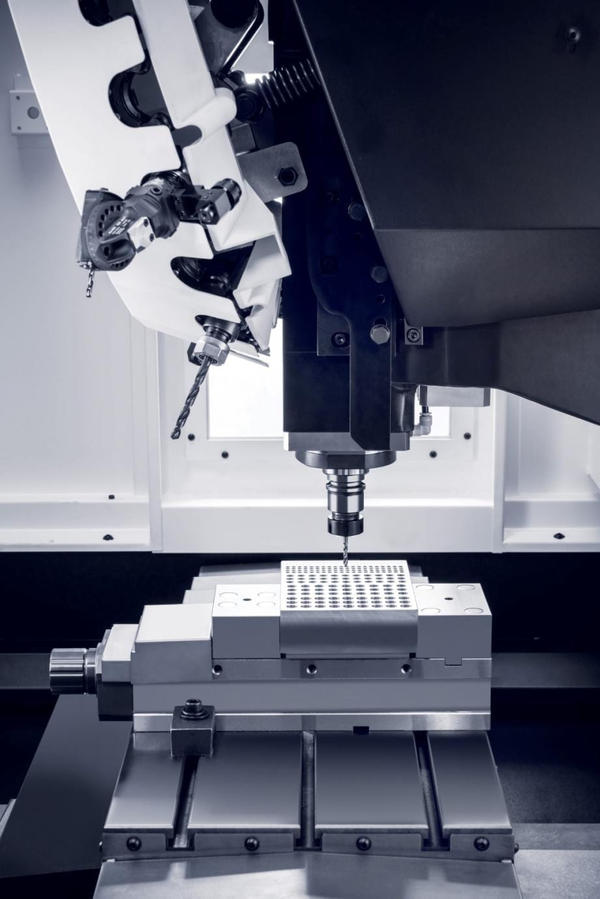

- High Speed Spindle

Standard tool: BBT30

- Spindles: 12k, 15k or 24k rpm

- Direct Spindle connection offers rigid tapping as well as mini tap

- Minimized thermal displacement through ceramic bearing

- Tool magazine size: 21 tools

High Speed Feed Rate

- Max. Rapid traverse: 60/60/60 m/min

- Stable traverse

- Low noise and high precision through ball screw tubeless

Mechanical specifications

| HiT-400 | HiT-400L | |

| Table Size [mm] | 600 x 400 | 800 x 400 |

| Axis Stroke (X / Y / Z) [mm] | 520 / 400 / 300 | 700 / 400 / 300 |

| Rapid Speed (X / Y / Z) [m/min] | 60 / 60 / 60 | |

| Spindle Speed [rpm] | 12k, 15k, 24k | |

| Spindle Power [kW] | 7.5 | |

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Double Column Vertical CNC Machining Centers

SIRIUS-2500

- Double Column Vertical CNC Machining Centers

SIRIUS-1750

- Double Column Vertical CNC Machining Centers

SIRIUS-1350

- Vertical CNC Machining Centers

VESTA-500T