A600

HORIZONTAL MACHINING CENTER

For Flexible Machining Of Parts & Components

A-600 is built with highly rigid box on box design for stable machining, its small footprint is perfect for FA system integration.

- Motor-integrated spindle: 16,000 rpm (22/18.5 kW) and HSK-A63 (opt. 8,000 rpm HSK A100)

- Rapid feed(X/Y/Z): 60/60/60 m/min

- Compact footprint is suitable for factory automation

- Rigid X/Y axes (Box in box design)

- Highly rigid roller guides in all axes

High-performance Spindle

The spindle integrated motor limits vibration, noise and power loss at high speed operations. The oil-jet system injects directly into the spindle bearing for effective lubrication and cooling, the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, the spindle constantly monitors for thermal displacement and makes necessary adjustment in real time.

High-precision Feed Drive

The linear roller guide way system ensures stable and smooth processing, the direct-coupled servo motor minimizes backlash during traverse. The machine automatically injects the lubricant onto the linear guide and the ball screws to maintain precision and functionality.

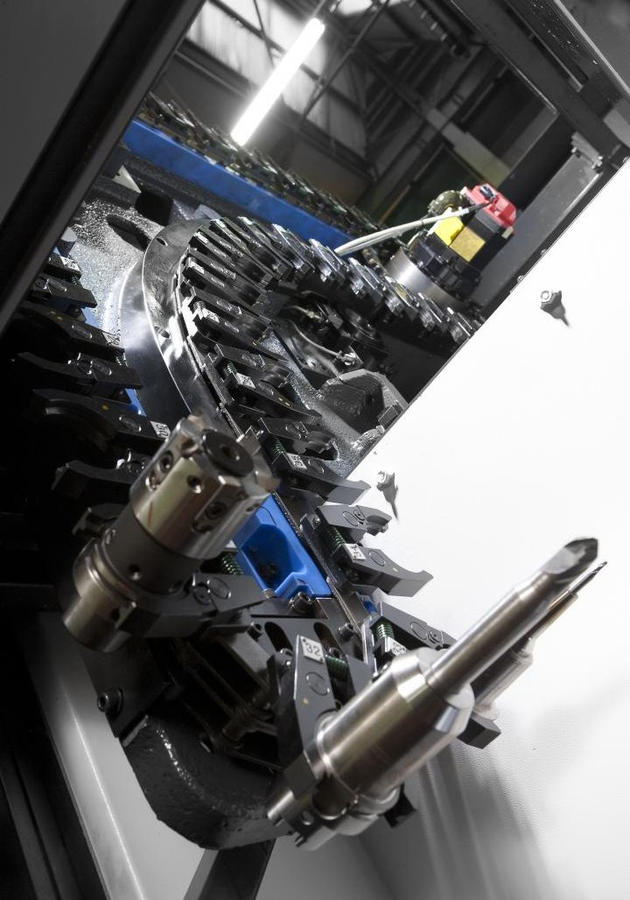

B-axis Drive

The servo motor’s precision worm gear design increases the motor’s torque, and the large-capacity oil-pressure brake system provides stable and accurate machining when performing fixed-angle roughing and boring.

Mechanical specifications

| Stroke (ISO#40type) (X / Y / Z) [mm] | 600 / 600 / 800 |

|---|---|

| Stroke (ISO#50type) (X / Y / Z) [mm] | 560/580/800 |

| Spindle (ISO#40Type) | 16k, 8k |

| Spindle (ISO#50Type) | 8k |

| Table Loading Capacity [kg] | 600 |

| Max. Spindle Speed [rpm] | 16,000 (8,000) |

| Spindle Motor Power [kW] | 22 / 18.5 |

| Type of Tool Shank | HSK-A63 (HSK-A100) |

| Tool Storage Capacity [Amount] | 40 (Opt. 60) |

| Floor Space (Length X Width) [mm] | 6,353 x 1,824 |

| Feedrate Rapid Speed (X / Y / Z) [m/min] | 60 / 60 / 60 |

| B-axis Rotation Angle | 360° |

| Table Size (Width x Length) [mm] | 500 x 500 |

Processing sample

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Double Column Vertical CNC Machining Centers

SIRIUS-1750

- Vertical CNC Machining Centers

VESTA-500T

- Vertical CNC Machining Centers

VESTA-610D

- Vertical CNC Machining Centers

VESTA-850B