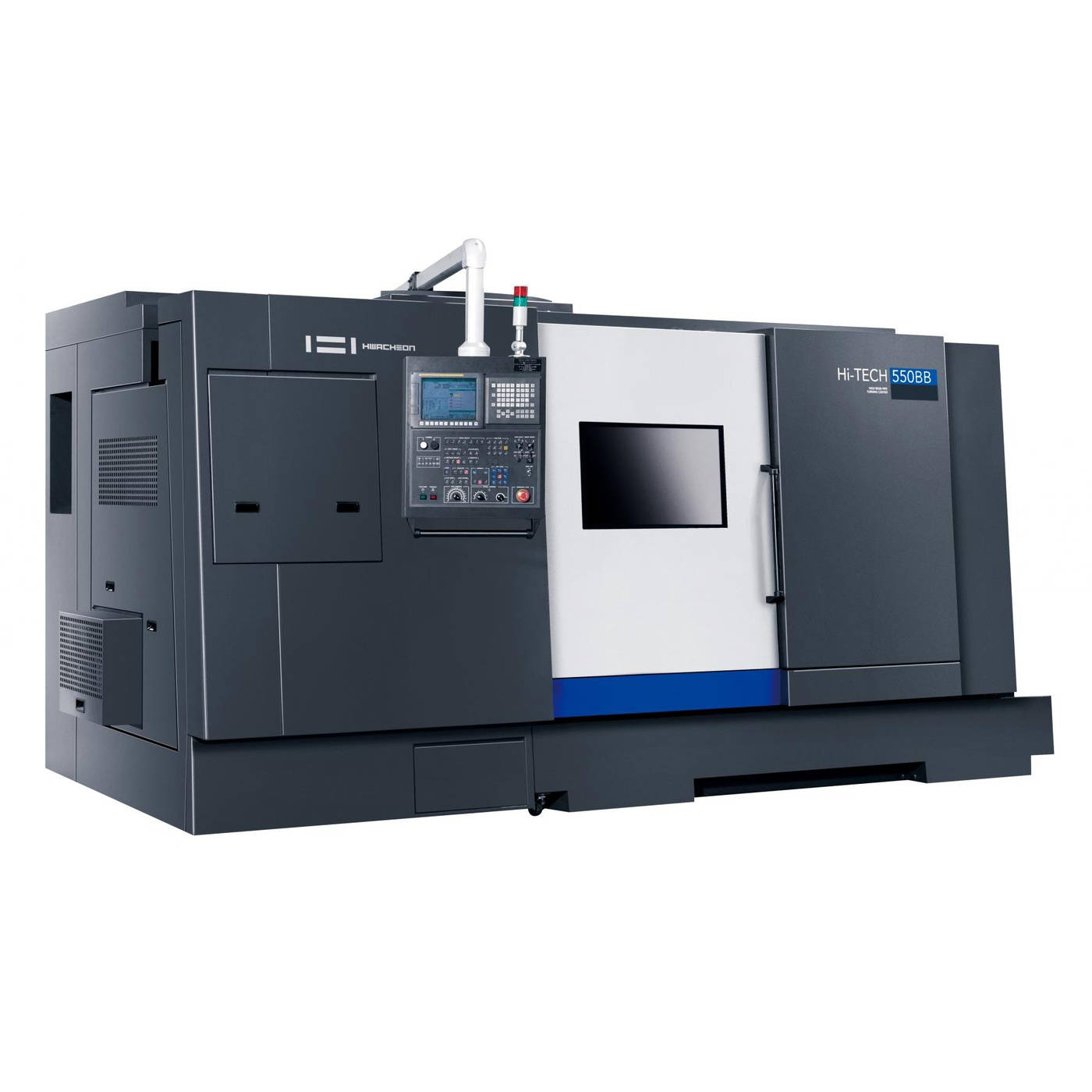

Hi-TECH 550BB

HIGH RIGID BIG BORE TURNING CENTER

Designed For Most Demanding Industrial Applications

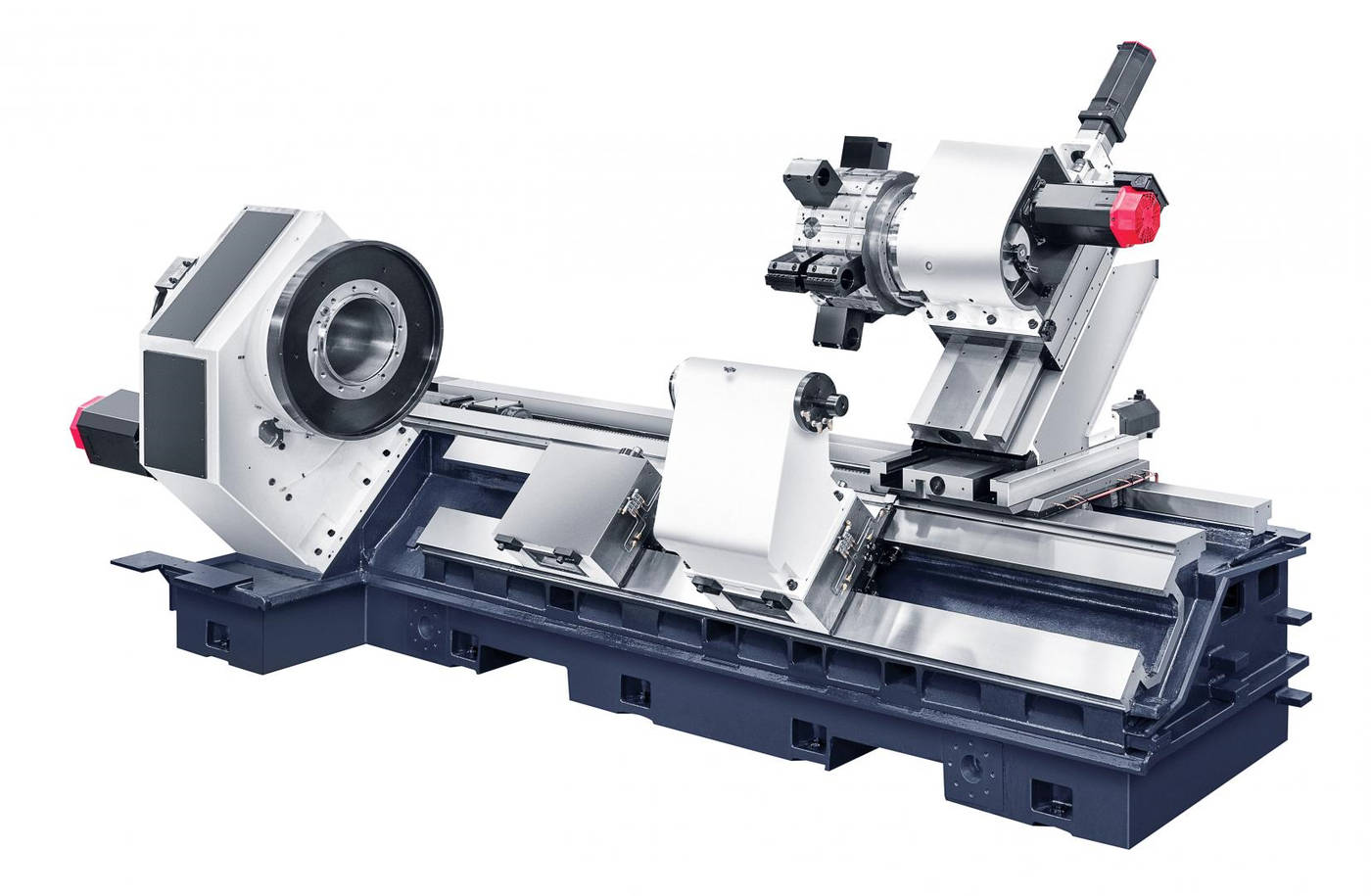

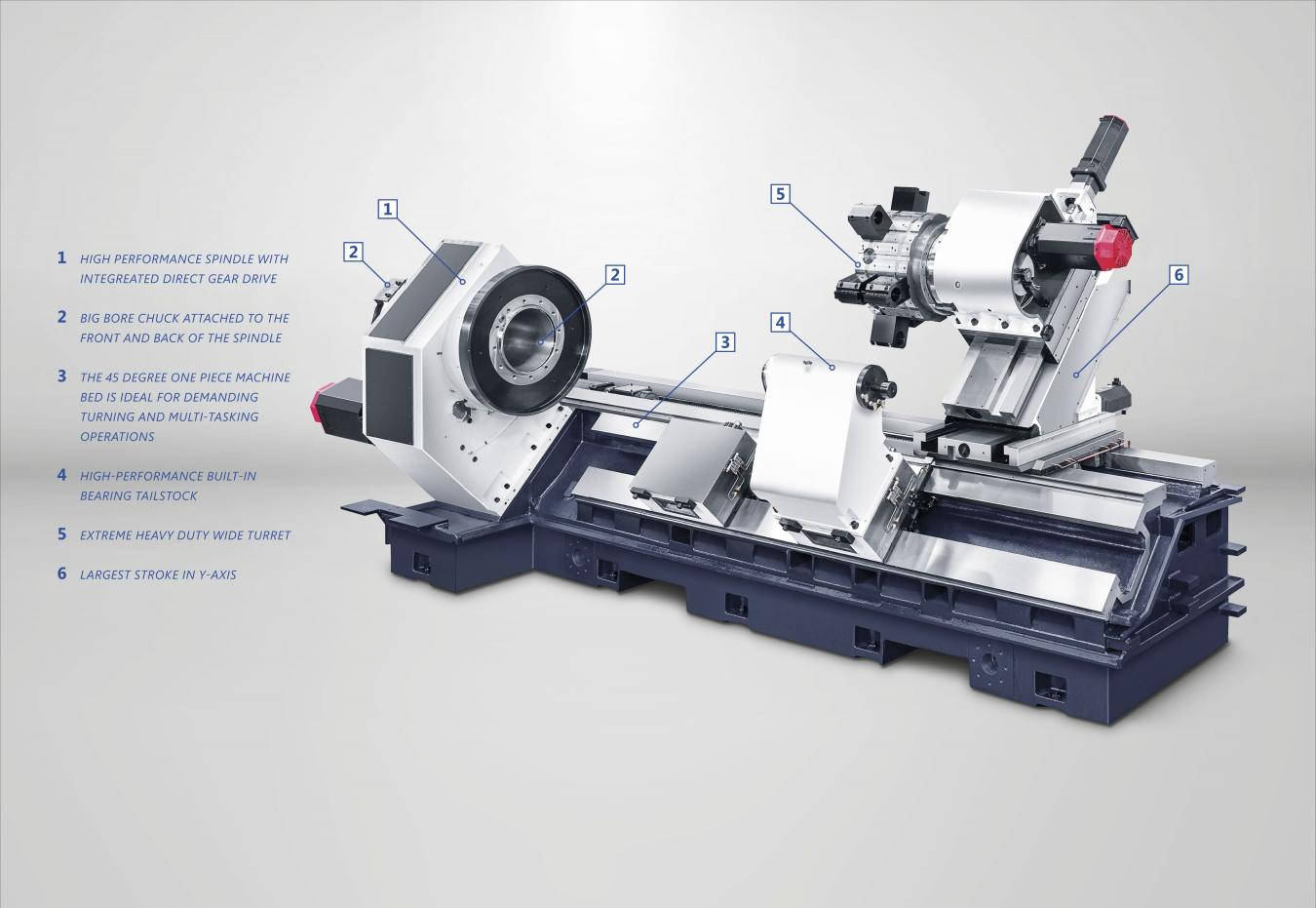

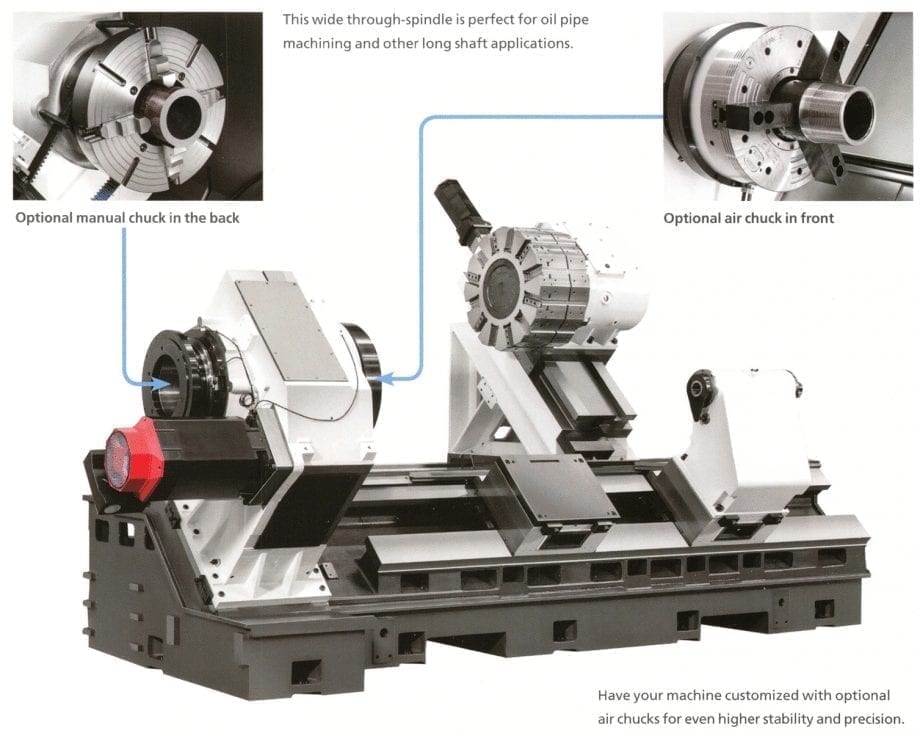

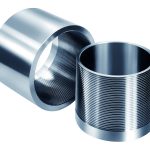

These tough, highly precise machines employ extra-size through-spindles, the two heavy duty air chucks in front and rear of the spindle guarantee perfect results, every time (optional).

The 45-degree unibody bed equipped in each model is ideal for most demanding turning jobs. The Hi-TECH BB series turning centers equipped with box way design in all guide ways for maximum stability and precision even after hours of prolonged operation. The gear-transmission spindle assembly provides both low-torque and high speed turning capabilities with increased productivity.

- Swing over bed: 800 mm

- Max. Cutting length: 1,150 mm (Opt. 2,150 mm / 3.200 mm)

- Optional Air-Chuck with diameter 18.5″

- Inner spindle bearing diameter: 240 mm

- Strong spindle motor with 37/30 kW

High Performance Spindle

The performance spindle delivers high torque at low speed, supported by the gear box system. The bearings at spindle assembly are oil cooled, with Hwacheon’s unique Oil Jet Cooling technology; the gearbox temperature is efficiently regulated with the circulating oil coolant for precision results at all time. This spindle system is specially effective for large size, heavy duty jobs such especially for oil and gas applications.

High Performance Turret

Entire process from turning to milling can be performed with a single setting. This helps maintain your quality, and eliminates down time in between jobs by getting rid of unnecessary loading and unloading of work pieces. It’s like having two machines in one, which means you’ll be twice as productive.

Multitasking

Run by a powerful AC spindle motor, the turnmill system can accurately axis-index the spindle to perfectly mill, tap, or drill. Different types of milling or turning job can be performed with a single chucking.

User Friendly Design, A Wide Range Of Optional Features

The BB-series of turning centers are designed with end users in mind. Its user-friendly machine design and a variety of supplementary features ensure a stronger, faster and more precise machining performance.

Mechanical specifications

| Item | Hi-TECH 500BB |

|---|---|

| Axis-Stroke (X / Y / Z) [mm] | 345 / – / 1150 |

| Spindle power [KW] | 37 / 30 |

| Spindle speed [rpm] | 1500 |

| Spindle torque [Nm] | 3364 / 2730 |

| Rapid speed [m/min] | 20 / – / 24 |

| Tool shank | BMT-75 / BH |

| Number of tools | 12 |

| Machine weight [kg] | 10000 |

| Max. cutting diameter [mm] | 590 |

| Max. cutting length [mm] | 2100 |

| Chuck-Size [mm] | 470 |

| Swing over bed [mm] | 800 |

| Max. Bar size [mm] | 190 |

| Coolant tank vol. [liters] | 250 |

| NC System | Fanuc 0i-TF (Opt. : Fanuc 31i-B) |

Processing software

- L-HTLDHwacheon Spindle Displacement Control System

Learn more about Hwacheon processing software

Related products

- Vertical CNC Turning Centers

VT-650

- Twin Spindle CNC Turning Centers

TTC-10

- Big Bore CNC Turning Centers

Hi-TECH 850BB / BB+

- Horizontal CNC Turning Centers

Hi-TECH 700