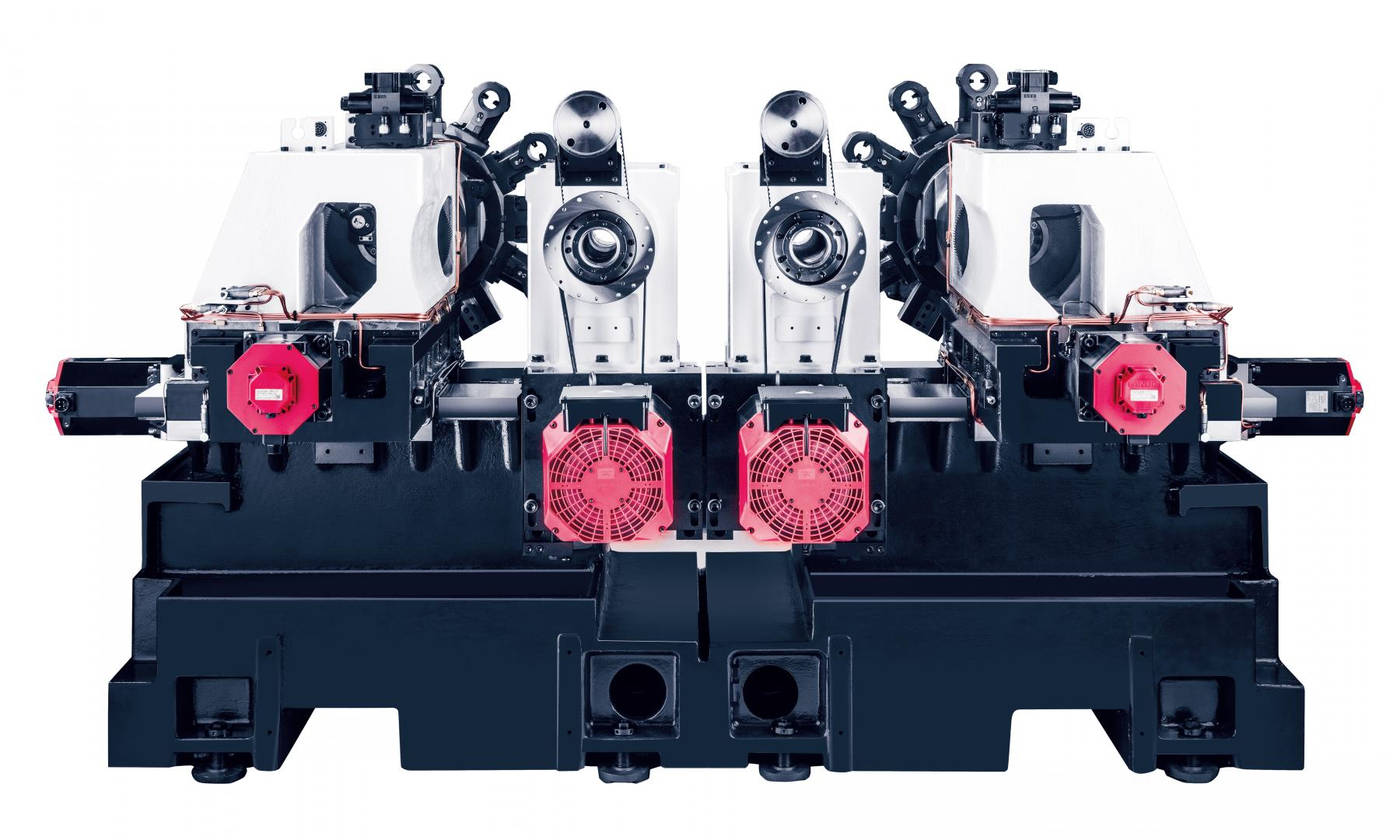

TTC-10

HEAVY DUTY TWIN-SPINDLE TURNING CENTER

TTC-10 turning center have been the preferred choice for many manufacturers around the world. The machine has demonstrated exceptional capabilities by machining many kinds of flanges and discs. Operated by the two spindles independently, it realize easy operations of workpieces at left side to right side. The one piece machine bed design limits thermal distortion and absorbs vibration effectively and guarantees high surface quality and precision at high speed. The fast and effective chip disposal design will make your production more efficient and cost effective.

- Highly rigid twin spindles: 2,000 rpm (18.5/15 kW)

- Unibody bed design for limited thermal displacement

- Turret indexing time (1 face): 0.4 s

- Rapid feed (X/Z): 30/30 m/min

- Simultaneous roughing and finishing

- Machine structure for easy chip-disposal

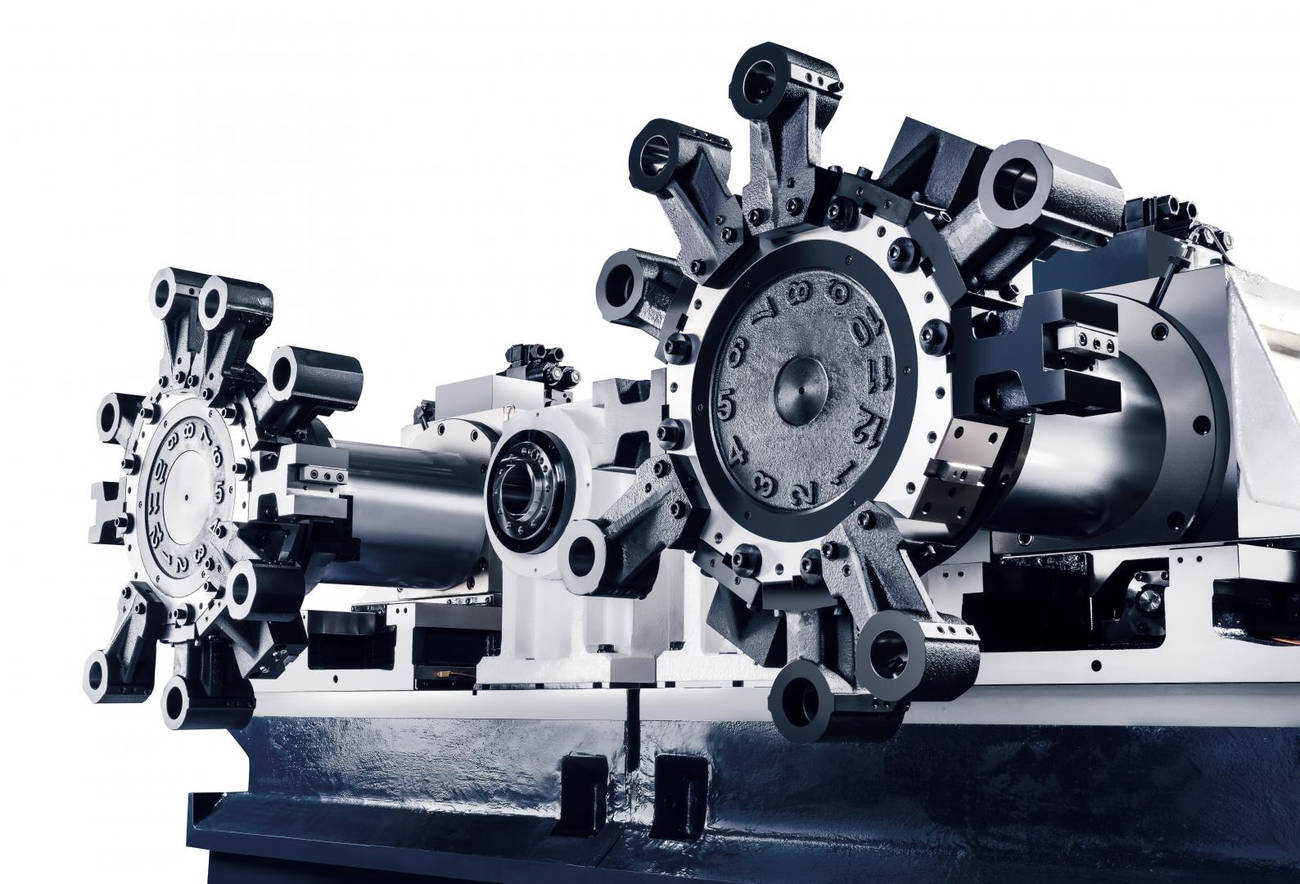

The TTC-10 is a twin spindle lathe (front) with two 12-position turrets and two working spaces. It is used by companies all over the world to cut particularly tough and hard materials, such as alloys based on titanium and nickel, or hardened steel, and is ideally suited to automated operation by means of a portal loader.

The wide Turcite-coated box guideways and the heavy machine bed form the foundation needed for these demanding tasks. Optimised swarf removal and numerous software features make the TTC-10 the perfect lathe for continuous heavy work, whether manually or automated.

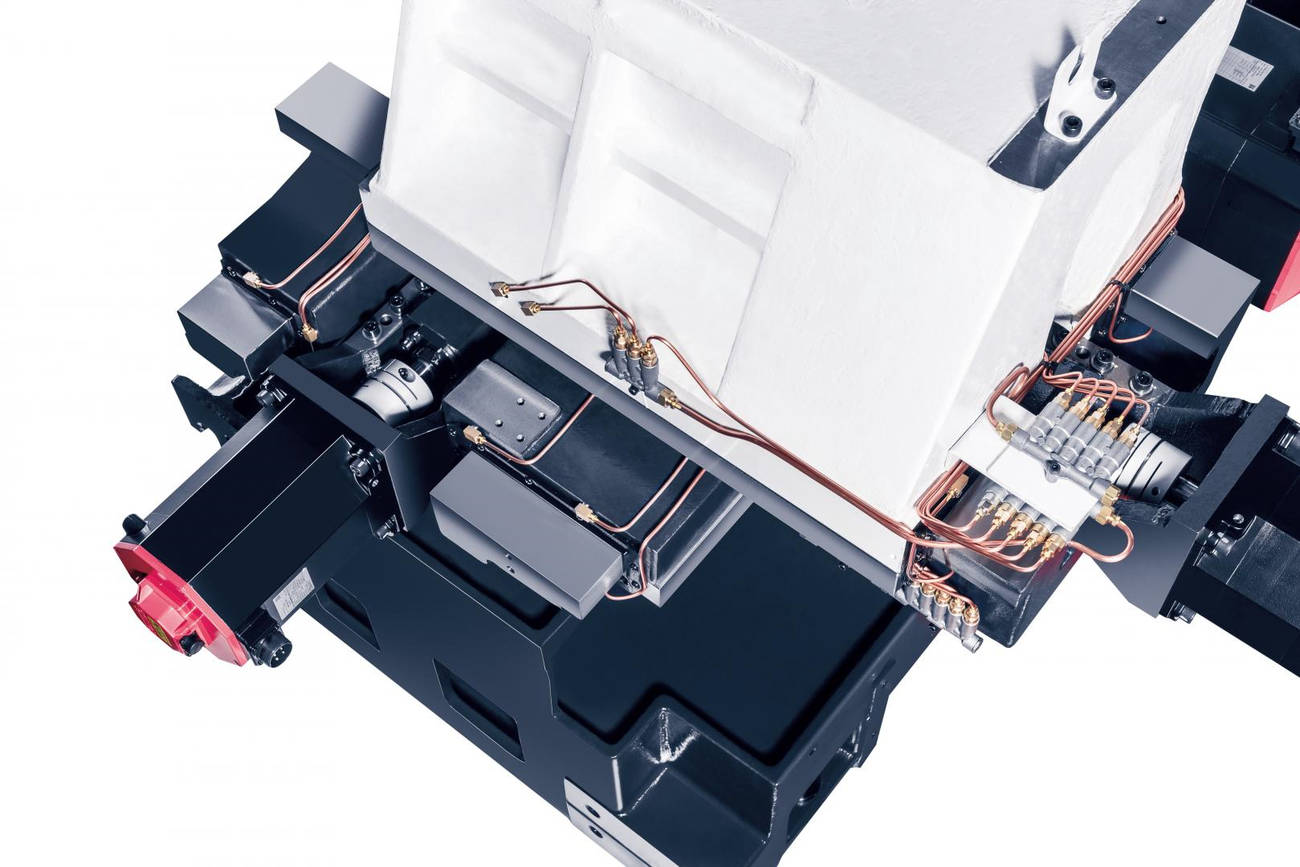

Integrated, Ultra-durable Bed With Column Type Turret

The machine is designed with a integrated 45-degree angle bed frame to minimize heat distortion, the precision- wide guide way surface and the unique bed design absorb vibration effectively during precision hard turning. All guide surfaces are rectangular and incorporate turcite to maintain rigidity and accuracy in prolonged operation.

Rigid, quick indexing turret

Hydraulic index motor type turret Number of tool stations: 12+12 Turret clamping force: 8,400 Kgf | Tool size: □ 25 × Ø50 | Chip-to-chip(100mm): 2 secs

Advanced Chip Management

The coolant tank is designed separately from the chip conveyor to prevent any heat transfer, the wide chip bucket can be easily removed for increased efficiency during maintenance work.

Mechanical specifications

| Swing over bed [mm] | Ø500 |

|---|---|

| Max. cutting diameter [mm] | Ø400 |

| Max. cutting length [mm] | 203 |

| Chuck size [mm] | 2 x 254 |

| Through spindle hole diameter [mm] | Ø77 |

| Max. spindle speed [rpm] | 2000 |

| Spindle motor power [kW] | 18.5 / 15 |

| Spindle torque | 691 / 560.8 |

| Feedrate rapid speed [m/min] | 30 / 30 |

| Feedrate max. stroke [mm] | 215 / 230 |

| Numer of tool stations [amounts] | 2 × 12 |

| Tool shank | BH |

| Machine weight [kg] | 9400 |

| Coolant tank vol. [lt] | 380 |

| NC System | Fanuc 0i |

Processing software

- L-HTLDHwacheon Spindle Displacement Control System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Turning Centers

Hi-TECH 750

- Horizontal CNC Turning Centers

Hi-TECH 230

- Vertical CNC Machining Centers

VESTA-1300B

- Vertical CNC Machining Centers

VESTA-1050B