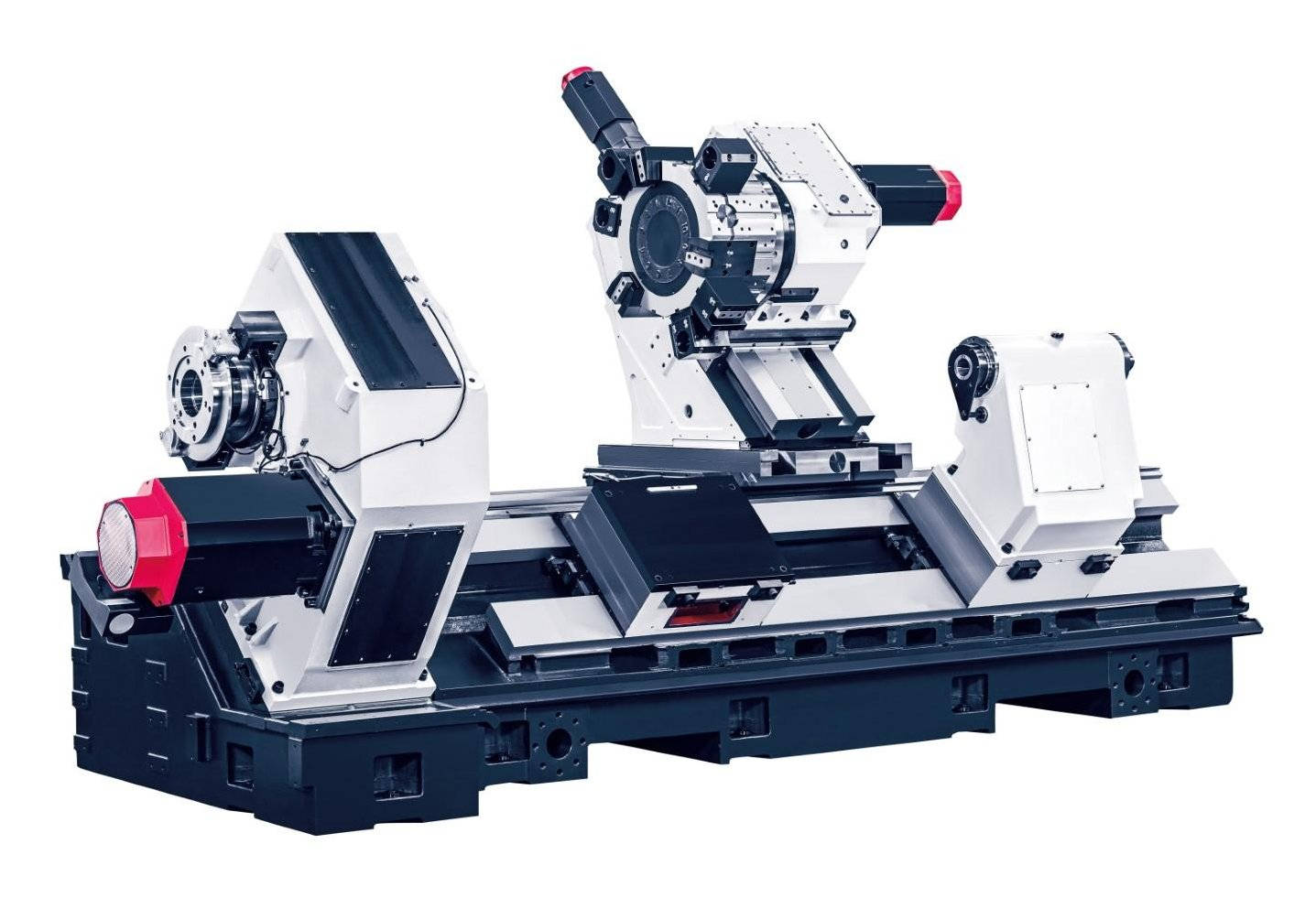

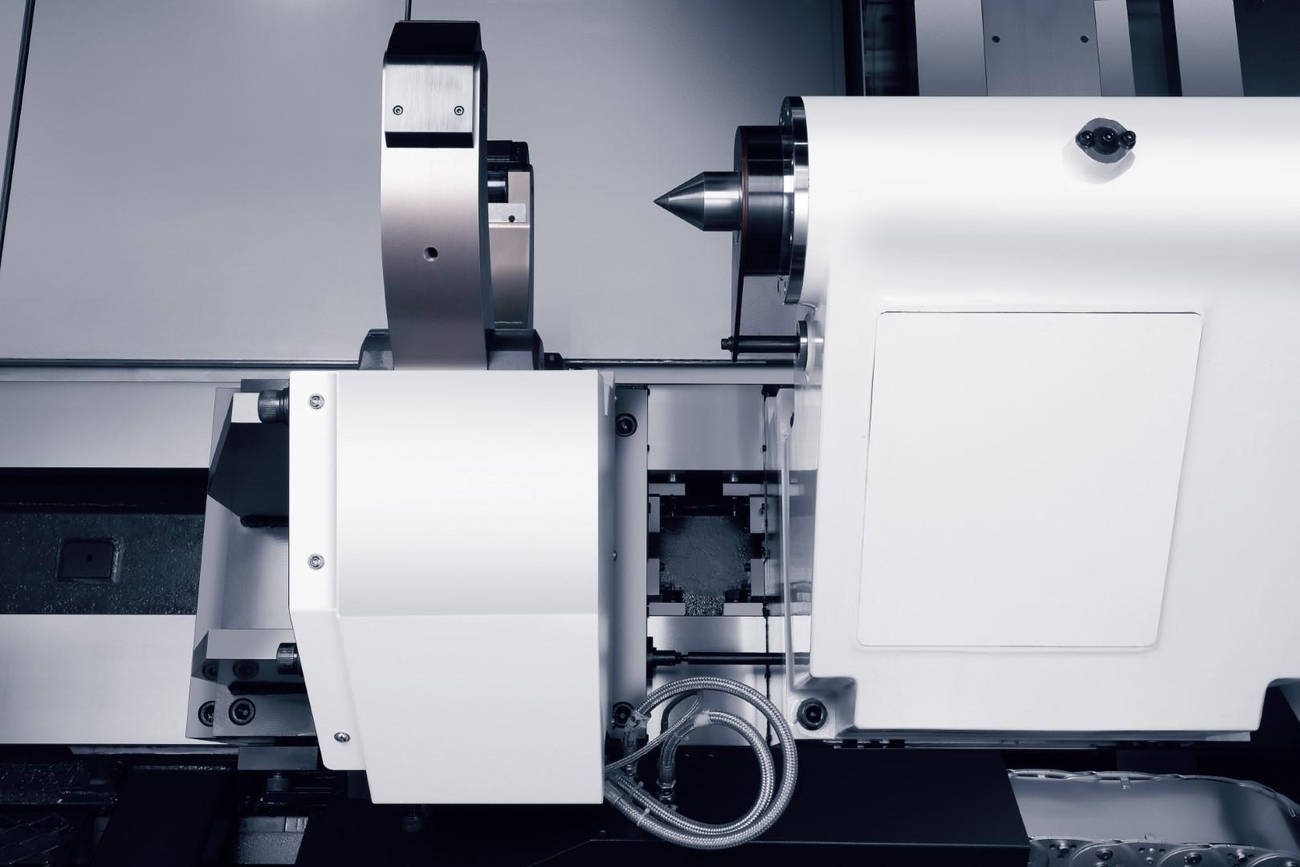

Hi-TECH 750

EXTRA-LARGE HORIZONTAL TURNING CENTER

Highly Rigid & Heavy Duty Machining

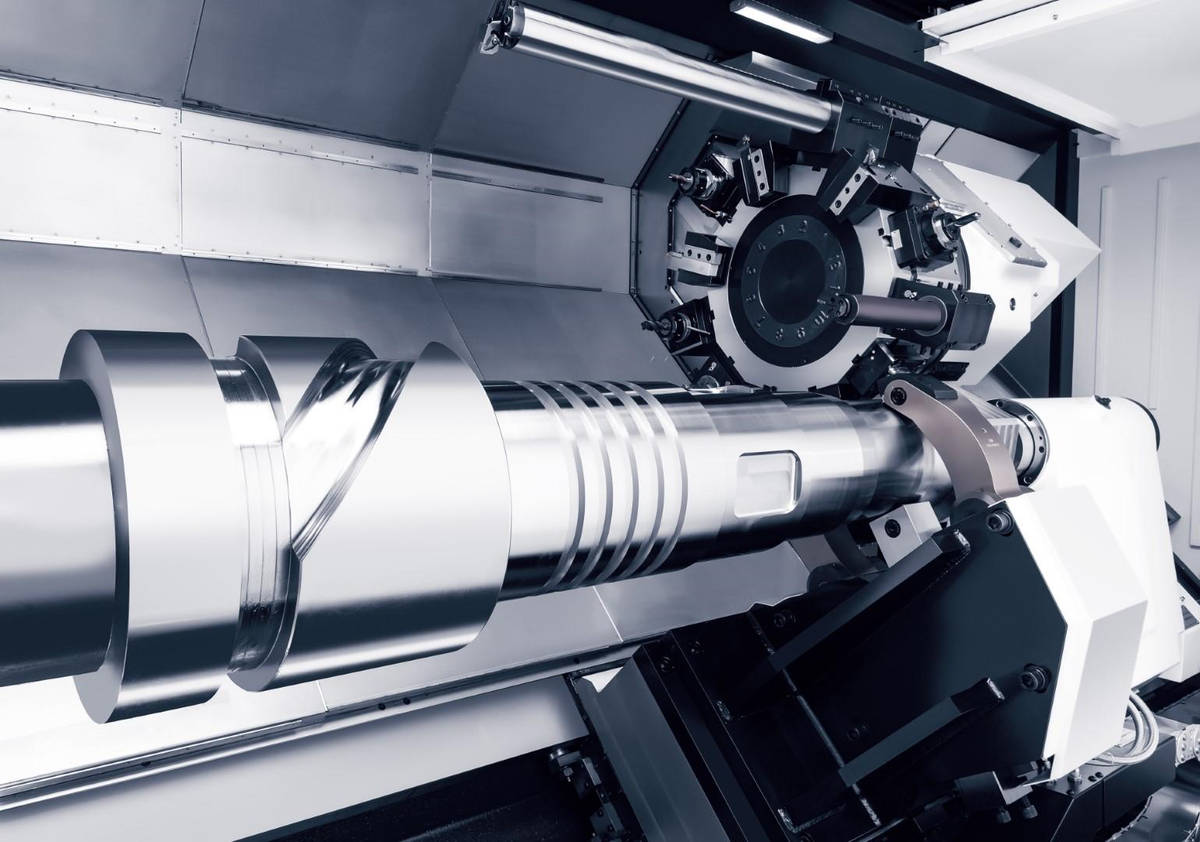

Hi-TECH 750 is capable of handling a wide variety of complex jobs from turning to milling in a single process. Its extra-wide (280mm) and extremely rigid Turret, the stability provided by the one piece casting bed and the extra wide dimensioned box way design are ideal for turning of large sized workpieces made off even strongest materials.

- High-Precision and powerful turning spindle: 45/37 kW / Torque up-to max. 6,560Nm

- Rigid box way slide design in all linear axis

- X / Z-axis Rapid rate up-to 18m/min

- Y-axis multiplex machining: 200 mm travel; 10 m/min Rapid rate

- Jet lubrication & cooling system for spindle bearing

- Boring capacity at ø80×800 mm (others optional)

Highly Rigid Spindle Design

Hi-TECH 750 has an integrated 45-degree slant bed frame to minimize heat distortion, all guide way are designed as solid Box guide ways to maintain rigidity and precision even during prolonged operations. Its automatic transmission system allows low-speed, high-torque turning as well as high-speed machining, the optional Y-axis ensures process integrated operations of complex large workpieces in one setting.

The largest cutting diameter and cutting length in its class (Ø760 / up-to 4,141 mm). The spindle, the tailstock and the steady rest system is designed and built to support heavy, large-diameter workpieces.

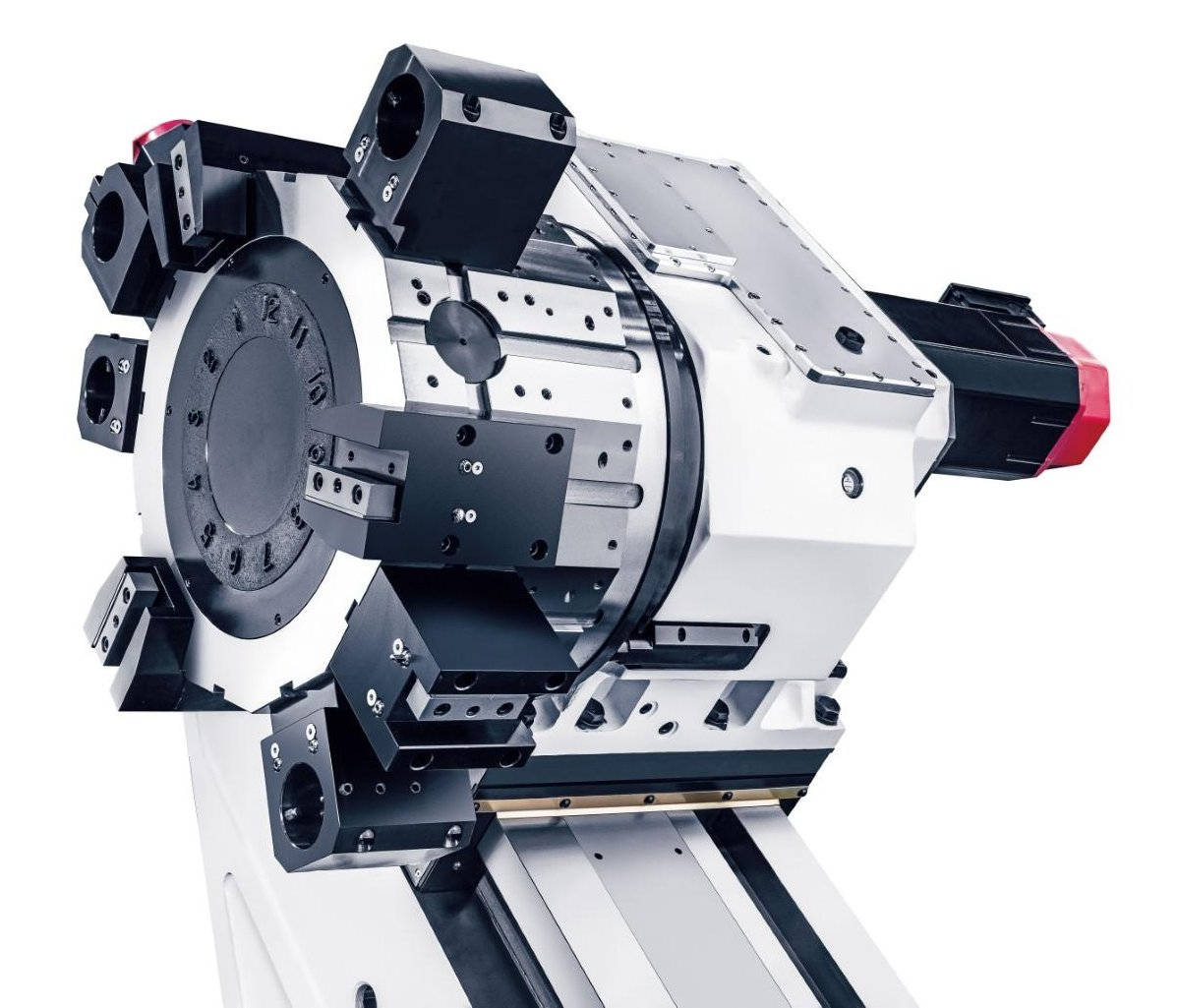

The turret unit is sitting and moving at a flat box guide way design above the 45 degree slant bed. Ensuring highest stability and best cutting support during even most complicated operations.

Gear-Driven Spindle System

The two gear speed transmission with the high performance gear decelerator provides highest amount of torque at low speed. The bearing assembly is cooled and lubricated by Hwacheon’s unique Oil-Jet cooling system, the gear box temperature is regulated by oil circulation for consistent spindle performance. The modern two gear system with powerful main drive motor provides best cutting conditions for any application requirement.

User Friendly Design and A Wide Range Of Optional Features

Hi-TECH 750 is designed with the end user in mind. Its user-friendly machine design and a variety of supplementary features ensure a stronger, faster, flexible and more precision performance.

The Hi-Tech 750 has been designed based on the very positive experience of our bigger Hi-Tech 850. Based on worldwide customer feedback we implemented many improvements and up-grades to a state of the art modern design and specification.

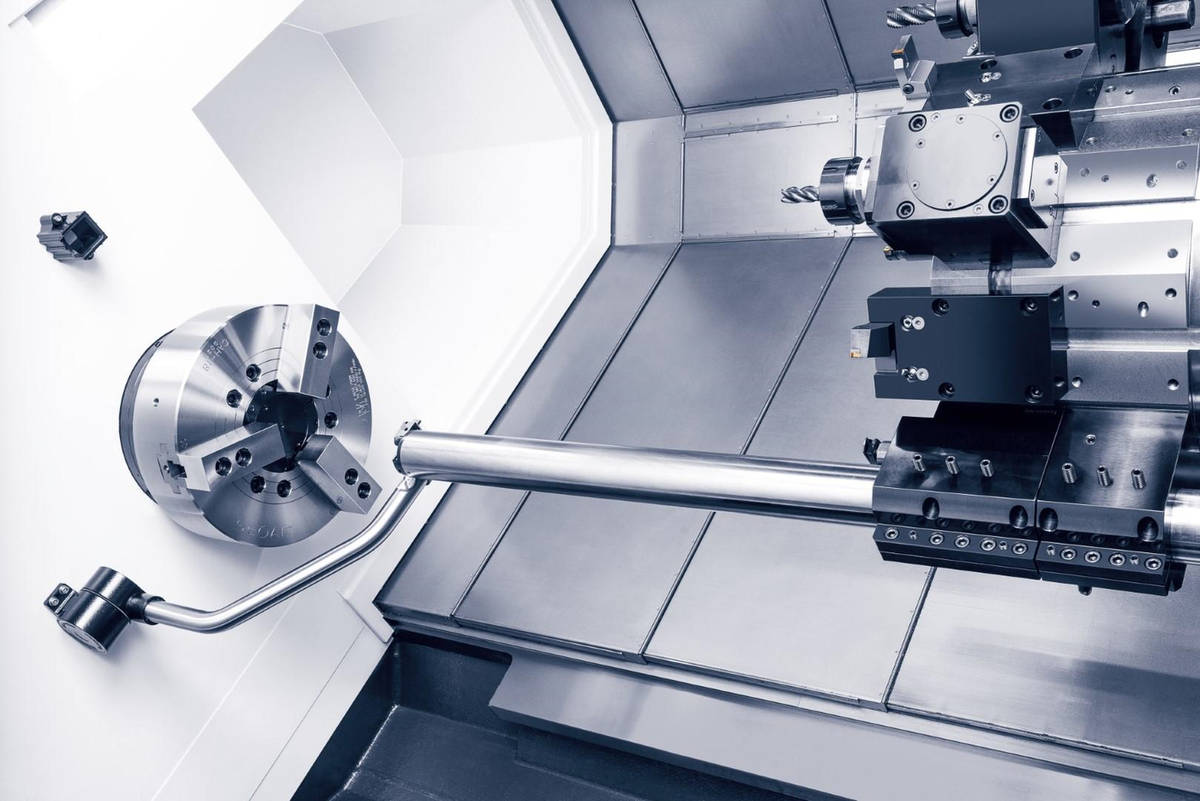

Extra-Long Boring Bar

Maximum diameter / length of the boring bar: D = Ø80 mm / L = 800 mm

Maximize your productivity by adding a Y-axis to your Hi-TECH 750 center. This is an ideal option if you want to complete complex processes including turning and milling in a single setting. An added Y-axis will save time and avoid secondary clamping of your part, eliminating down time and increase your profitability.

Mechanical specifications

| Swing Over Bed [mm] | Ø1200 |

|---|---|

| Max. Cutting Diameter [mm] | Ø760 |

| Max. Cutting Length [mm] | 4250 |

| Chuck Size [mm] | 15 – 24” |

| Max. Spindle Speed [rpm] | 1800 |

| Bar Capacity [mm] | Ø164 |

| Spindle Motor Power [kW] | 45 / 37 |

| Tool Storage Capacity [Amount] | 12 |

| Feedrate Rapid Speed (X / Z / Y) [m/min] | 18/18/10 |

| Max. Stroke (X / Z / Y) [mm] | 430/4350/200 |

| NC System | Fanuc 0i-TF |

Processing software

- L-HTLDHwacheon Spindle Displacement Control System

Learn more about Hwacheon processing software

Related products

- Vertical CNC Turning Centers

VT-350

- Big Bore CNC Turning Centers

Hi-TECH 850BB / BB+

- Horizontal CNC Turning Centers

Hi-TECH 550

- Horizontal CNC Turning Centers

CUTEX-180