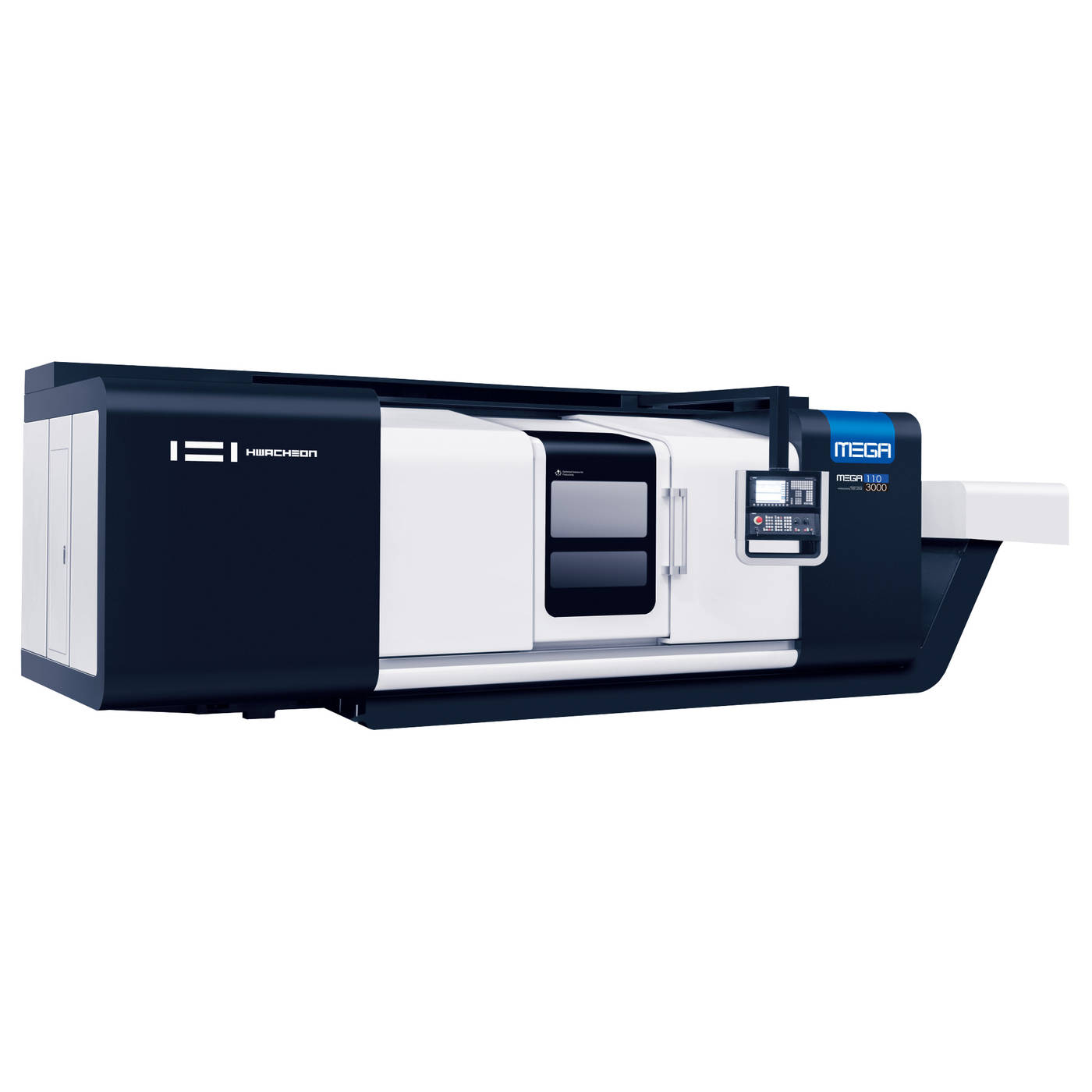

MEGA-110

HEAVY DUTY HORIZONTAL CNC TURNING CENTER

High Rigid Structure & Performance

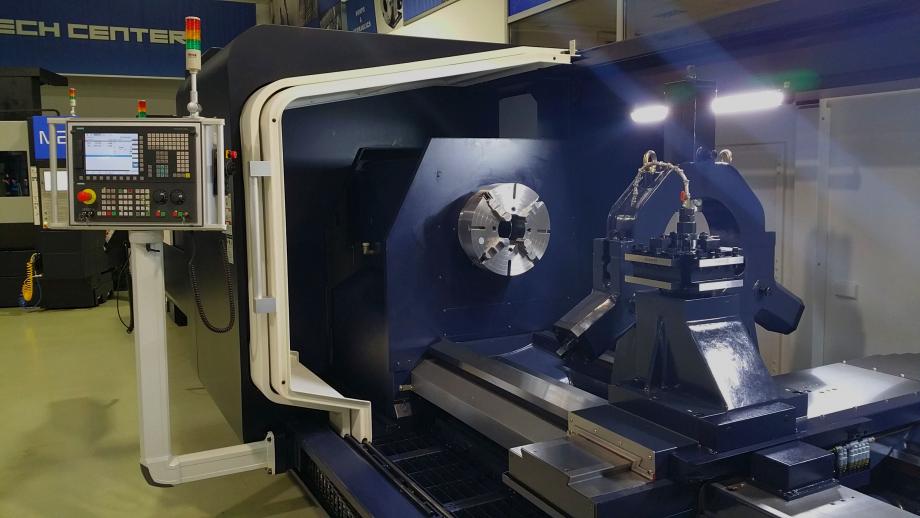

Heavy Duty CNC Lathe specifically designed for ship building, wind power, new energy, mining, oil & gas, heavy-precision parts for aircraft industry. MEGA-110 offers CNC and hand wheel control for very small batch production with a 1,100 mm swing diameter. The lathes in the MEGA series have been specially developed for the production of very small batches, repair jobs and particularly heavy and large workpieces. In addition to numerical control, the MEGA series is also equipped with hand wheels. This means that these machines can be used like conventional lathes, which is particularly advantageous for repair work and rework machining.

- Very user friendly operation

- Heavy duty cutting

- High stability

- Four bed sizes: 3, 4, 5 and 6 meters turning length

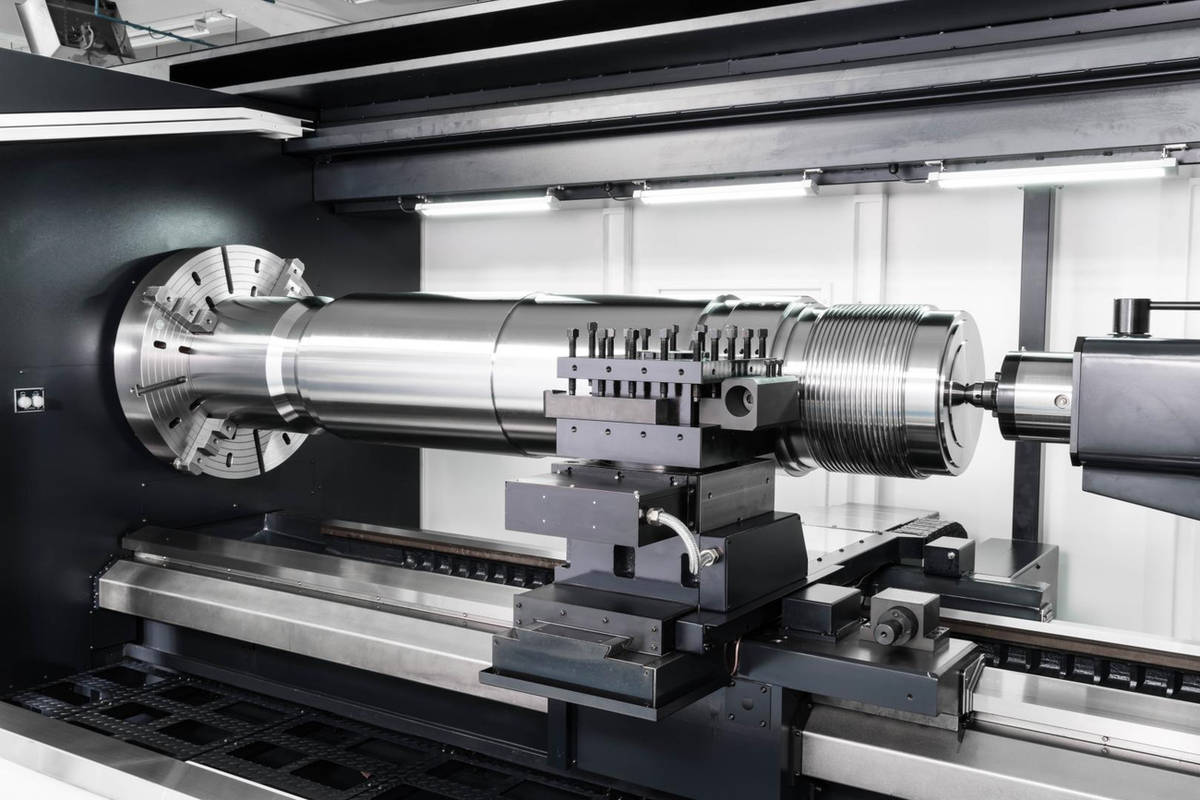

The high drive power of 55 kW (up to 2,165 Nm) and the very broad guideways guarantee a stable and efficient cutting process. With the MEGA-110, workpieces with a weight of up to 12 tonnes and a turning length of up to 6 m can be machined with ease.

High Accuracy

- Adoption of ball screw and servo motor

- Easy checking for spindle speeds through spindle position encoder

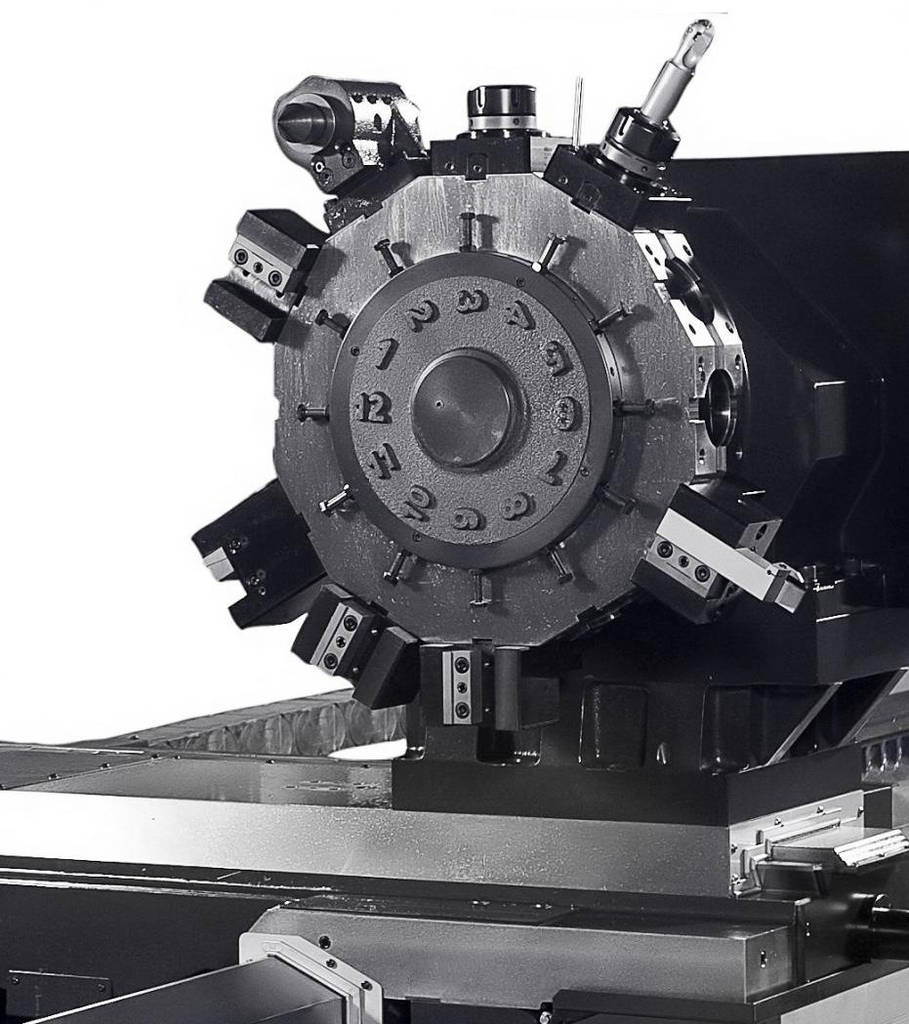

- Guarantee of repeatability ±5° by adoption of curvic toolpost. Other toolpost on customer’s demand (i.e. Parat) !

Utmost Convenience

- Excellent operation & easy loading/ unloading work piece by convenient operation panel

- Semiautomatic tailstock feeding device

Heavy Duty Cutting

- Heavy duty cutting and precision turning by one piece fabricated bed & leg structure

- High rigid headstock

- Spindle through hole ∅155 mm : four point contacts with ball bearing, cylindrical roller bearing, angular bearing

- Spindle through hole ∅255 mm : three point contacts with taper roller bearing

- Spindle through hole ∅320 mm : three point contacts with taper roller bearing, double roller bearing

- Ball screw

- X-axis: ∅32 x 6 mm

- Z-axis: ∅50 x 12 mm (3000T/4000T), ∅63 x 12 mm (5000T), ∅80 x 12 mm (6000T)

- Guide way : Turcite

High Stability

- Maintaining high accuracy by using turcite laminated slide surfaces

- Application of high pressure lubrication pump to guarantee perfect lubrication on slide surfaces

- Prevention of operation error by lock type mono lever switch (Opt. Fixed MPG handle)

Mechanical specifications

| Swing Over Bed [mm] | Ø1180 |

|---|---|

| Max. Cutting Diameter [mm] | Ø820 |

| Max. Cutting Length [mm] | 3,000 – 6,000 |

| Distance Between Centers [mm] | 3,000 – 6,000 |

| Spindle Nose | A2-15 |

| Spindle Power Motor [kW] | 56 / 37 |

| NC System | Fanuc 0i, Fanuc 31i |

Processing software

Related products

- Big Bore CNC Turning Centers

Hi-TECH 550BB

- Horizontal CNC Turning Centers

Hi-TECH 350

- Horizontal CNC Machining Centers

AF-16

- Double Column Vertical CNC Machining Centers

SIRIUS-1350