SIRIUS-2500 5AX

5-AXIS UNIVERSAL MACHINING CENTRE

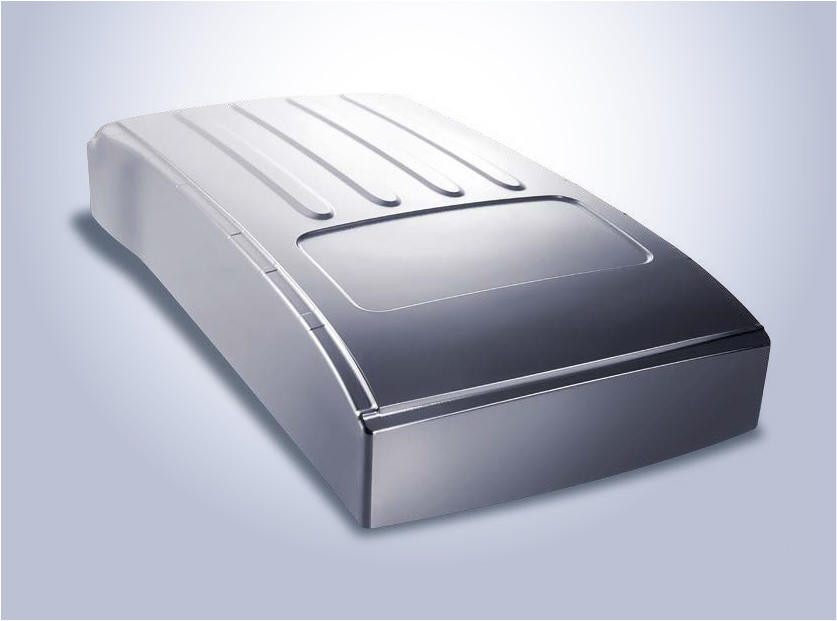

Optimal Solution For Machining Large & Complex Work Pieces

Hwacheon’s SIRIUS-2500/5AX is capable of machining large, complex work pieces and molds which demand complex operations. Along with the Hwacheon Total Solution, it is the production solution you’ve been looking for.

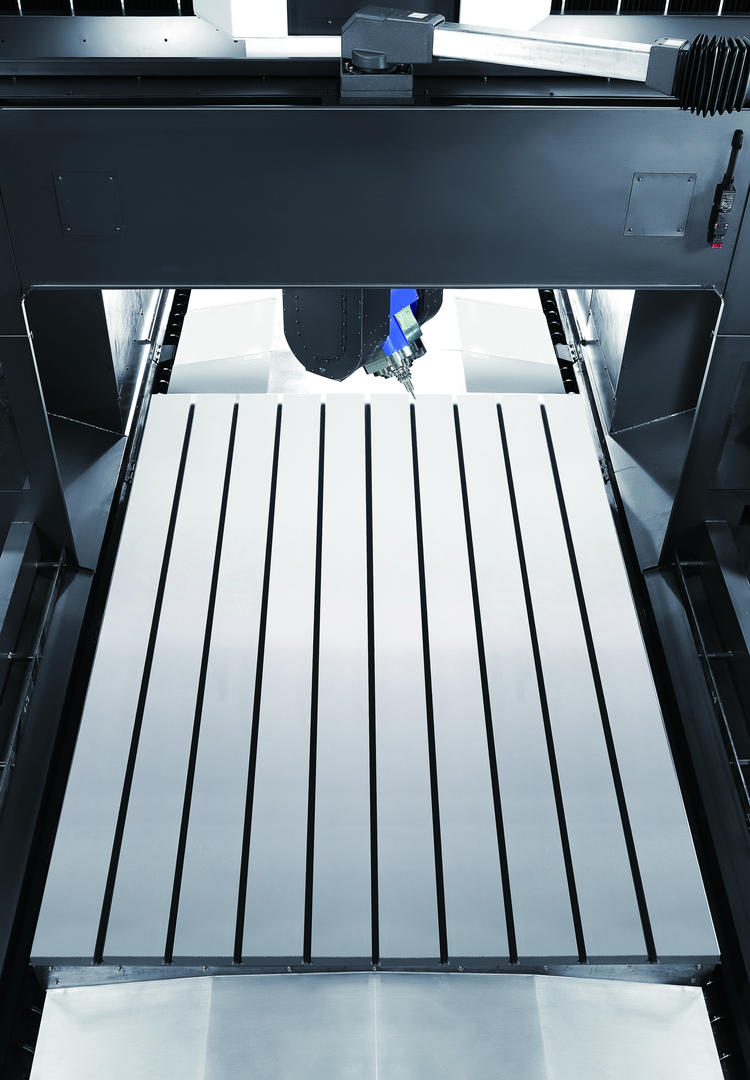

Stable, Symmetrical Portal-Type Structure

The double columns provide stable support for the Y-axis feed system, and the symmetrical structure that distributes the load, vibration, and heat of the upper area throughout the entire frame enables stable feed even during prolonged operation. Also, minimizing the distance between the Y-axis feed system and the tool’s machining point maintains rigidity and increases machining precision.

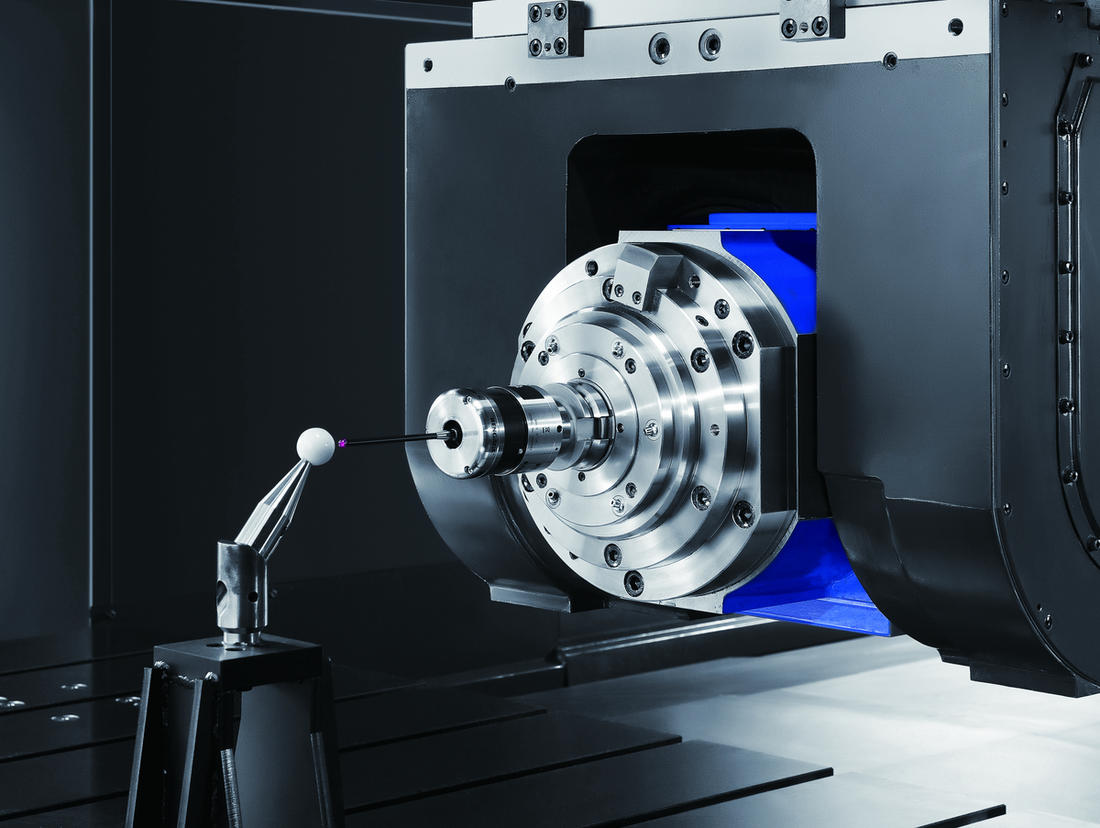

Direct Drive Type Rotation Axis

A direct-drive motor is integrated with a high-precision encoder without any mechanical transmission such as gears, which minimizes backlash and enables high-precision angle division of .001° as well as high-speed rotation feed at 30 rpm, thereby increasing precision and reducing machining time. Also, a powerful hydraulic brake system ensures sufficient rigidity during 3+2 axis machining.

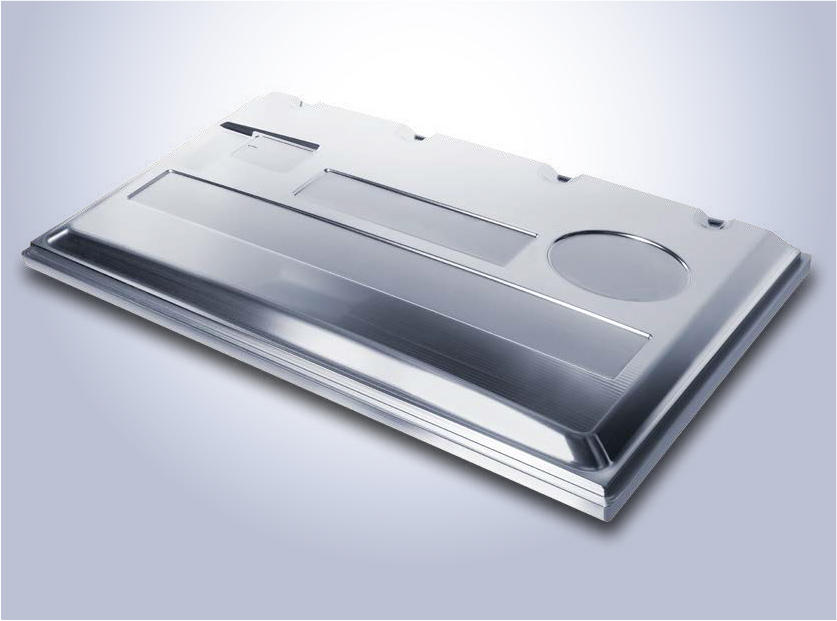

High-Efficiency Multi-Axis Machining

SIRIUS-2500 5AX can implement multiple processes with a single setting by machining even undercut area that cannot be cut by 3-axis. Instead of using ball-end mill to fine cut a surface, it utilizes the sweep function that cuts with the side and base of the end mill to reduce the machining time. It shortens the tool length and provides operations with the ball-end mill’s side blade rather than the end point leads to longer tool life and smooth cut surfaces.

Mechanical specifications

| Stroke (X / Y / Z) [mm] | 3,100 / 2,300 / 1,000 |

|---|---|

| Feedrate Rapid Speed (X / Y / Z) [m/min] | 16 / 16 / 16 |

| Rotation Angle (B-axis / C-axis) [deg] | ±100 / ±210 |

| Working Surface [mm] | 3,300 x 2,000 |

| Table Loading Capacity [kg] | 10,000 |

| Max. Spindle Speed [rpm] | 15,000 |

| Spindle Motor [kVA] | 18.5 / 11 |

| Type of Tool Shank | BBT-40 (Opt : HSK-A63, CAT-40) |

| Tool Storage Capacity [ea] | 40 |

| Floor Space (Length X Width) [mm] | 10,500 x 5,420 |

| NC Controller | Fanuc 31i-B5 |

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

- HRCCHwacheon Rotation Center Calibration System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Turning Centers

CUTEX-240

- Vertical CNC Machining Centers

SIRIUS-UL+

- Vertical CNC Machining Centers

VESTA-2000

- Vertical CNC Machining Centers

VESTA-1000+