VT-1150+

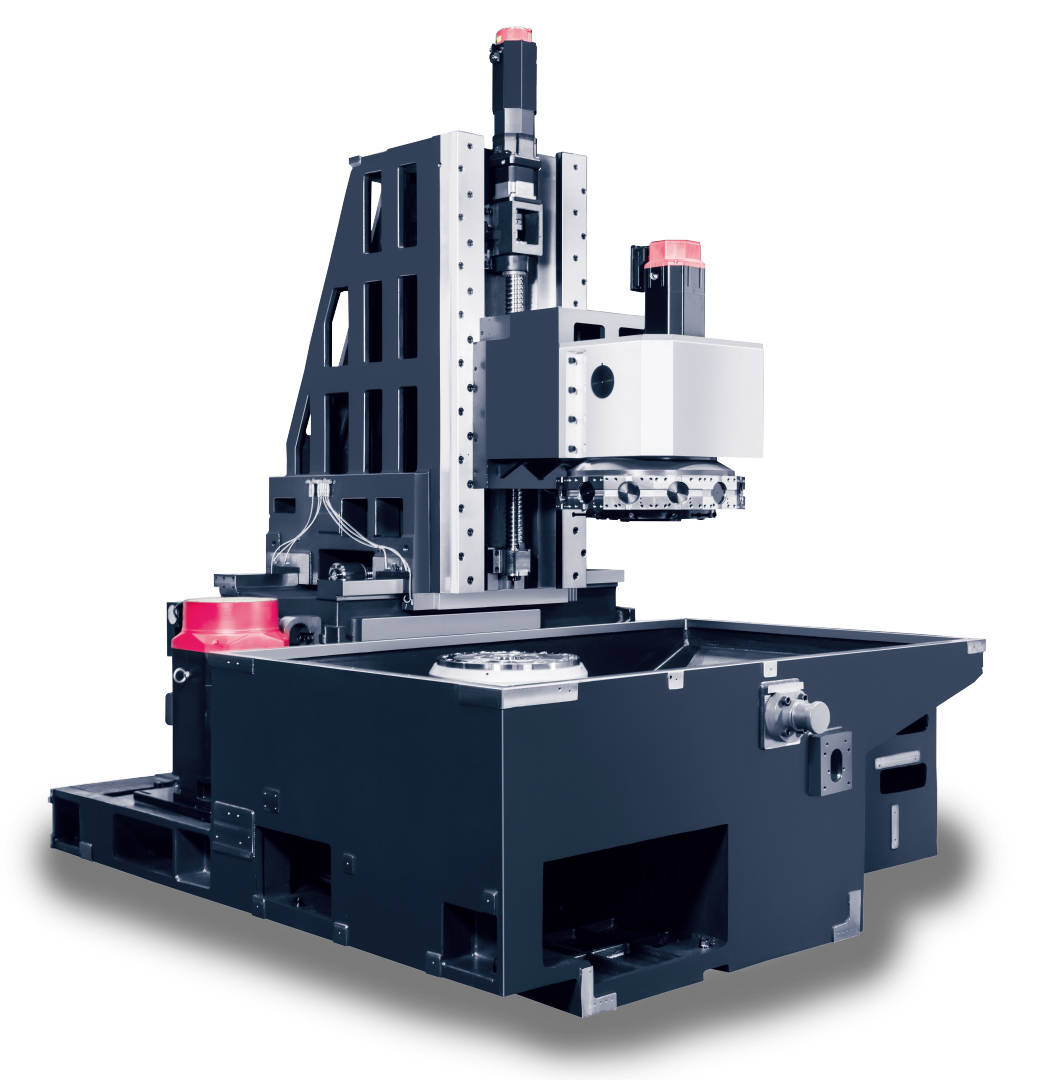

LARGE SIZE VERTICAL TURNING CENTER

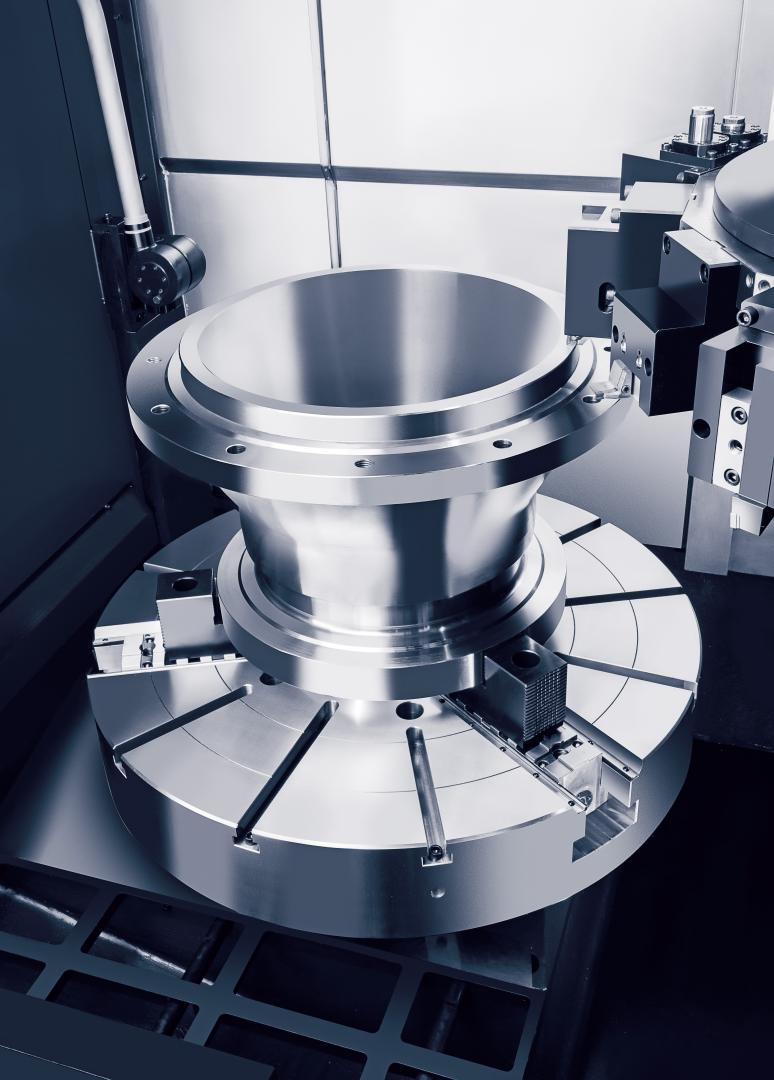

Built In Gear Box With 32″-50″ Chuck

The machines can handle a variety of complex processes from turning to milling and drilling in one setting. With the heavy duty structure this turning centers can cut down your machining process and make your work more precise and productive.

- Equipped with 40-inch chuck as STD

- Highly rigid bed design

- Powerful milling function optional

- Additional tool magazine optional available with Capto C6

- Environment-friendly lubrication-coolant separation design

- Spindle oil cooler with high-pressure lubricant pump and linear glass scale(STD)

Heavy duty cutting for large workpieces

VT-1150+ vertical turning center is the ideal machine for your large size applications. With precision hand scraped and grinded guide way system in all axes, the unique one piece machine bed design provides rigidity, built to absorb vibration and best stability. Hwacheon’s advanced air floating system keeps the operation stable and allows for smoothest operations.

Modern tough materials like inconel, titanium or heat resistant stainless steel are not a problem for this machine. A Giga Torque version is available as well.

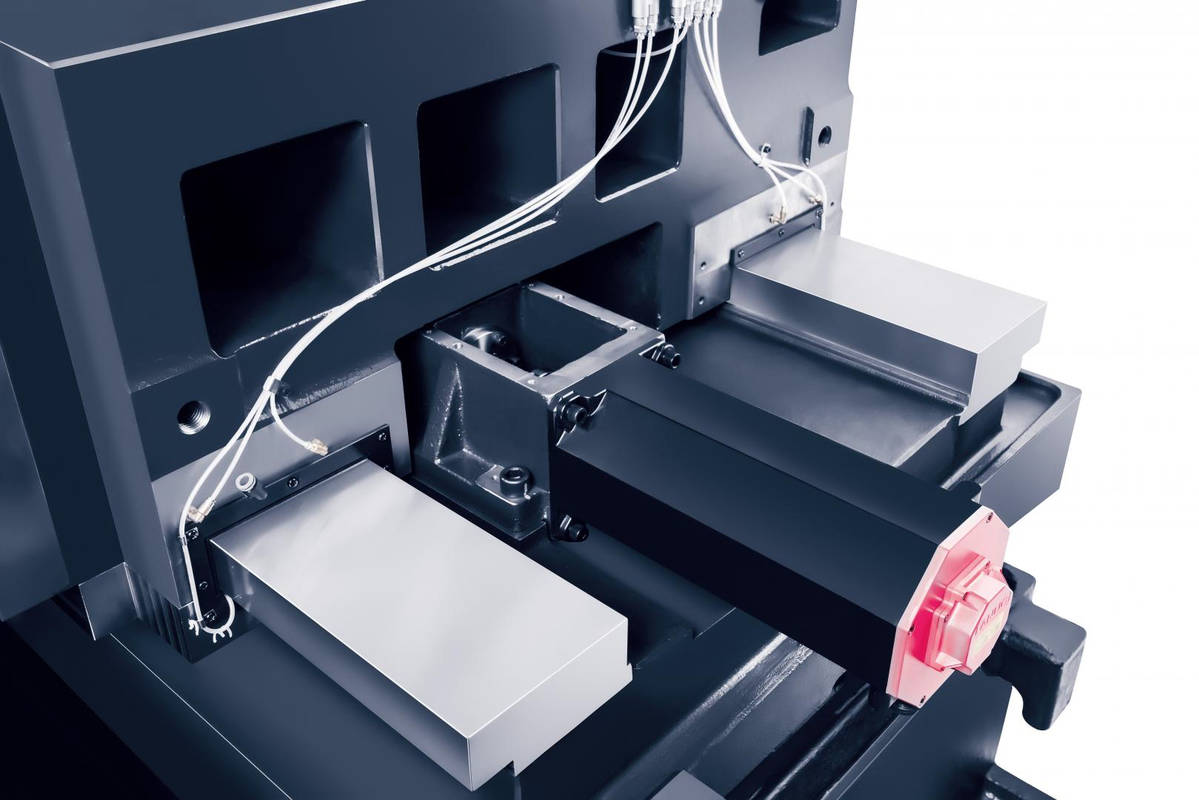

Tool magazine with Capto interface

In order to reduce frequent setting up, or for workpieces which require many tools, a second tool magazine is available, from which stationary and also very long tools can be automatically exchanged.

User friendly design, a wide range of optional features

VT-1150+ vertical turning centers are designed with the user in mind. The user-friendly machine design and a variety of supplementary features make for stronger, faster, and more precise machining performance.

High dynamism through air floating technology

Despite their high masses, with their rapid traverse speed of 24 m/min, the VT-950+ and the VT-1150+ permit dynamic machining with minimal non-productive time. This is achieved by means of Hwacheon’s perfected air-floating technology, whereby the box guideways are charged with compressed air. This significantly reduces the stick-slip effect and the break loose torque during start-up.

Mechanical specifications

| Swing Over Bed [mm] | 1350 |

|---|---|

| Max. Cutting Diameter [mm] | 1150 |

| Max. Cutting Length [mm] | 950 |

| Chuck Size [mm] | 1016 |

| Max. Spindle Speed [rpm] | 630 |

| Spindle Motor [kW] | 55 / 45 |

Processing software

- L-HTLDHwacheon Spindle Displacement Control System

Learn more about Hwacheon processing software

Related products

- Vertical CNC Turning Centers

VT-350

- Big Bore CNC Turning Centers

Hi-TECH 550BB

- Horizontal CNC Turning Centers

Hi-TECH 450

- Double Column Vertical CNC Machining Centers

SIRIUS-1350