C2

AUTOMATIC TOOL CHANGING MULTIPLEX TURNING CENTER

8” Chuck With Tool Magazine & Y-Axis

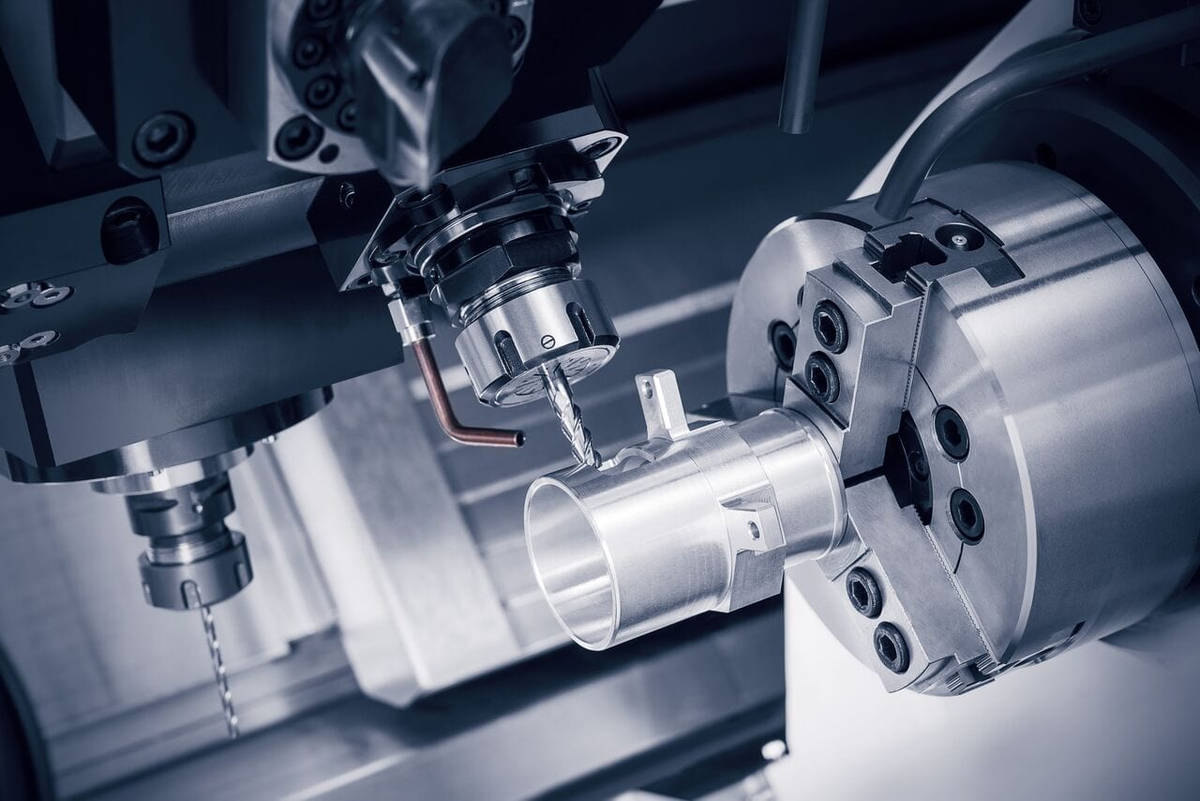

C2 is an integrated multiplex turning center that combines the processing capability of a turning center with the processing capability of a machining center obtainable through Y and C axis control. It can completely manufacture parts in complex geometry in a single chucking operation.

Ideal for complex workpieces in small batches – for maximum flexibility. Thanks to its travelling column design, with its orthogonal X, Y and Z axes, the C2 unifies the machining characteristics of a lathe with the fabrication characteristics of a machining centre. This means that workpieces with complex contours can also be machined to an exceptional level of precision. At the same time, a sub spindle allows two machining steps to be carried out without clamping errors.

Key Features:

- Independent orthogonal structure of X, Y, and Z-axes reduces feed error to zero, sustaining high rigidity and high precision even during prolonged processing

- The magazine can be loaded with various tools, enabling multiple lathing and milling processes in a single, uninterrupted operation.

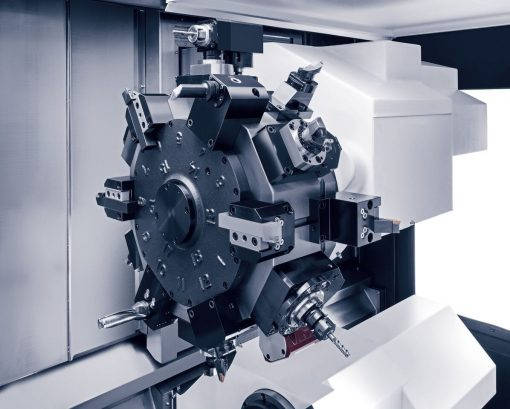

- High Precision, High Rigidity Turret – in a World First Design. Mounted with up to 18 tools, the turret enables even faster and more stable machining through multiplex operations.

- Quick tool change with Capto C4 system. Tool positions are widespread and do not interfere with each other. Wide selection of tools and tool holders for various applications any time.

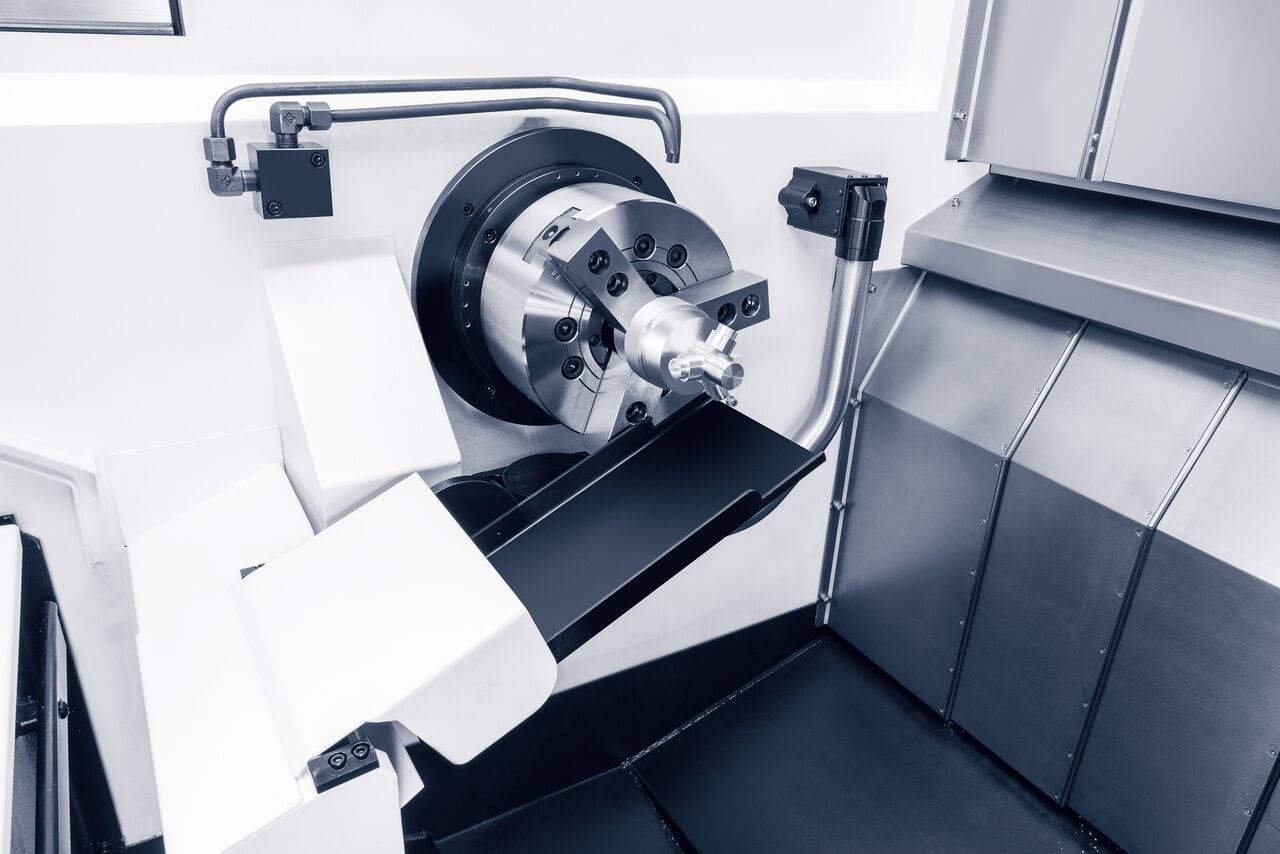

- Main spindle with 8” chuck (opt.10”) and 15 Kw power and a 477 Nm torque. Maximum 5,000rpm (subject to chuck size). Designed as “built-in” spindle (direct drive). Spindle housing with oil cooling standard.

- Optional sub-spindle with 6” chuck. Maximum 6,000 rpm and 15 Kw.

- Process integrated multiplex machining possible.

- Y-Axis with +/- 60 mm stroke in a single linear movement.

- Additional tool storage capacity through integrated tool magazine. Providing additional 11 tools to the system. Either single tools or complete tool holder is automatically interchangeable.

- Optional built-in part catcher and part conveyor providing unmanned operation cycles.

- All-in-one utilities giving a smooth machine layout without equipment standing outside the machine. Easy maintenance and servicing ensured.

- The machine structure ensures easy chip removable and discharge.

Mechanical specifications

| Swing Over Bed [mm] | Ø730 |

|---|---|

| Max. Cutting Diameter [mm] | Ø630 |

| Max. Cutting Length [mm] | 564.5 |

| Chuck Size [mm] | 8” (opt. 10”) |

| Max. Spindle Speed [rpm] | 5,000 |

| Max. Bar Size [mm] | 65 |

| Through Spindle Hole Dia [mm] | Ø76 |

| Spindle Motor (Upper / Lower) [KW] | 15 / 11 |

| Number of Tool Station [ea] | 18 |

| Rapid Speed (X/Z/Y/B) [m/min] | 30 / 30 / 15 / 30 |

| Max. Stroke (X/Z/Y/B) [mm] | 360 / 700 / ±60 / 705 |

| Turn Mill Spindle Motor [kw] | 5.5 / 3.7 (7.5 / 5) |

| NC Controller | Fanuc 0i-TF |

Processing software

- L-HTLDHwacheon Spindle Displacement Control System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Turning Centers

CUTEX-240

- Vertical CNC Machining Centers

L1 / L2

- Vertical CNC Machining Centers

HiREX-4000

- Vertical CNC Machining Centers

SIRIUS-UM