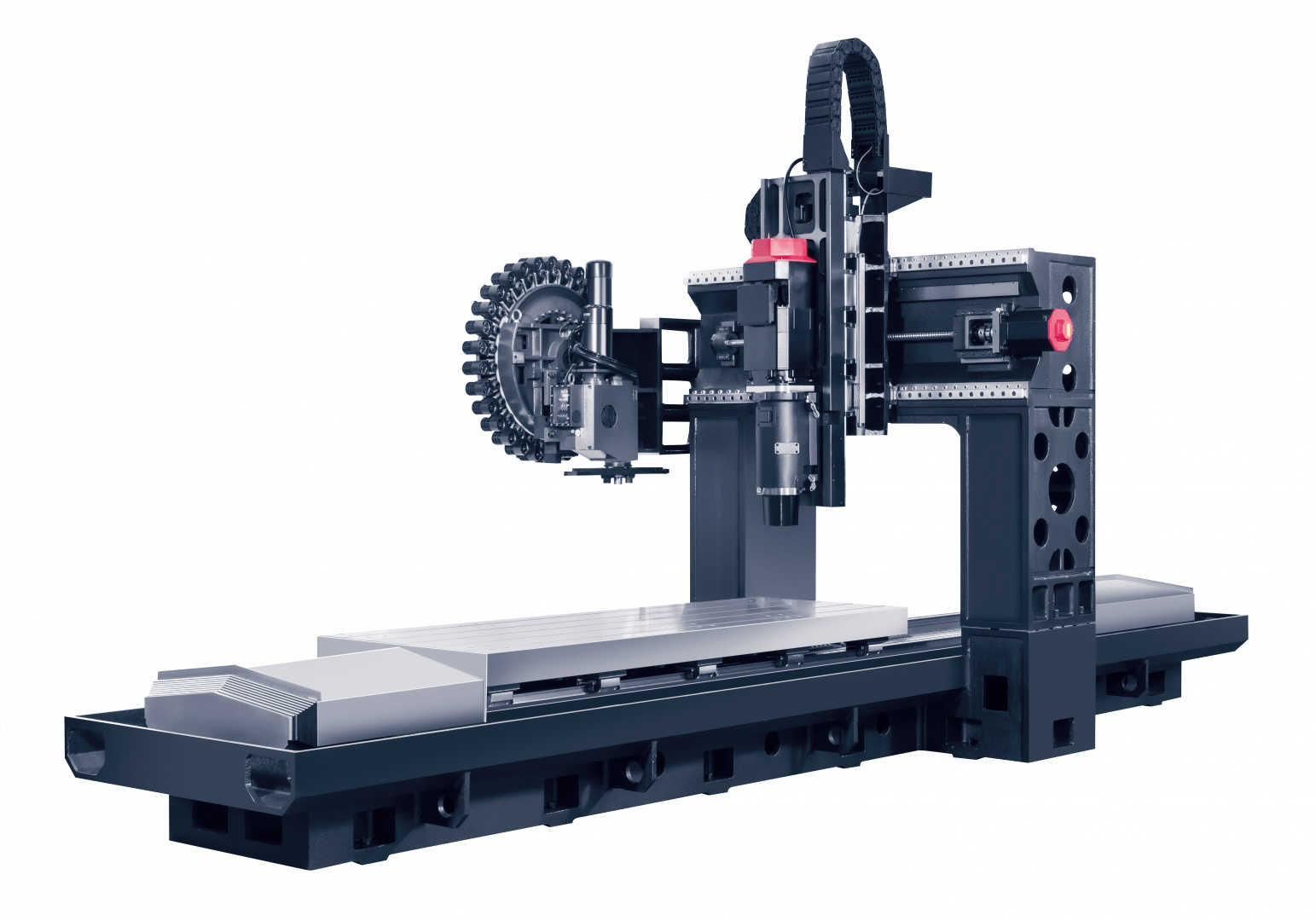

L1 / L2

DOUBLE COLUMN MACHINING CENTER FOR GENERAL LIGHT PARTS INDUSTRY

Stable double column structure provides high precision cutting performance. It is equipped with Hwacheon’s propietary technologies such as productivity enhancement software (HECC, HTLD and Optima) and precision enhancement software. L1 and L2 are optimized for machining of non-ferrous metal and IT/seminconductor equipment components, archieving high machining quality.

Category Vertical CNC Machining Centers

Tags 3 axis, Bridge / Portal type, Fanuc 0i, Linear guideway

High Performance & High Productivity

- Highly rigid roller type linear guideways on all axes

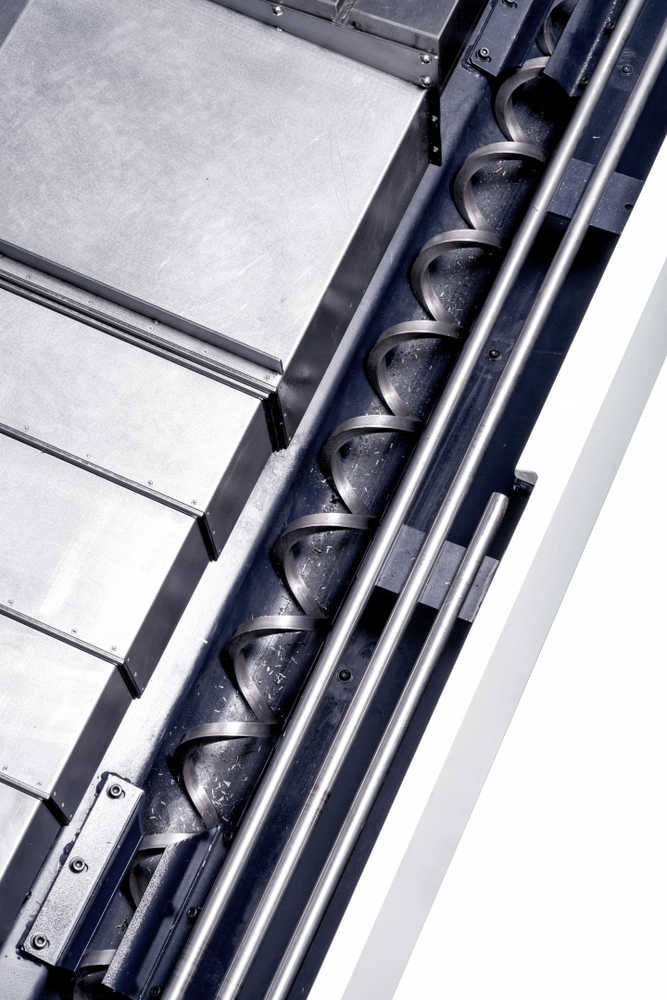

- Two side chip augers & rear discharge chip conveyor

- Extra wide working table allows multiple workpieces to be setup Hwacheon Software maximizes machine performance

Optimized for Light Duty Cutting

- High speed roughing & Finishing

- Specialized in aluminum machining

Maximum Operator Convenience

- Full enclosure design preventing chips and coolant from splashing outside the machine

- Wide door opening for easy loading/unloading of large workpieces

- Convenient and ergonomic operator access

- Chip conveyor and straight shape coolant tank designed for easy cleaning and maintenance

- Distance from floor to table surface 700mm, excellent access to table with no step platforms required

Specifications

Samples

Software

Specifications

Mechanical specifications

| Item | L1 | L2 | ||

| Stroke (X / Y / Z) [mm] | 1,500 / 950 / 500 | 2,500 / 950 / 500 | 2,500 / 1,100 / 500 | 3,000 / 1,100 / 500 |

|---|---|---|---|---|

| Rapid Speed (X / Y / Z) [m/min] | 24 / 36 / 36 | |||

| Feed (X / Y / Z) [mm/min] | 1 ~ 20,000 | |||

| Table Size [mm] | 1,500 x 900 | 2,500 x 900 | 2,500 x 1,100 | 3,000 x 1,100 |

| Table Loading Capacity [kgf] | 2,000 | |||

| Max Spindle Speed [rpm] | 12,000 | |||

| Spindle Motor [kW] | 18.5 / 11 | |||

| Type of Tool Shank | MAS-403 BT-40 | |||

| Tool Storage Capacity [ea] | 30 | |||

| Floor Space (L x W x H) [mm] | 6,000 x 2,945 x 3,250 | 7,590 x 2,945 x 3,250 | 7,590 x 3,155 x 3,250 | 8,900 x 3,155 x 3,250 |

| NC Controller | Fanuc 0i-MF | |||

Samples

Software

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Machining Centers

H8

- Vertical CNC Machining Centers

HiREX-4000

- Vertical CNC Machining Centers

HiT-360D

- Double Column Vertical CNC Machining Centers

SIRIUS-2500