HiREX-4000

TRAVELLING COLUMN MACHINING CENTER

HiREX-4000 can perform machining of a long material using its long table and perform multiple machining using jig & fixture, and partitions, achieving the production efficiency of two machines with one machine.

- High precision heavy duty machining.

- High efficiency with long stroke table (X-axis: 4,000 mm).

- Same effect as 2 machines with Partition (Opt.).

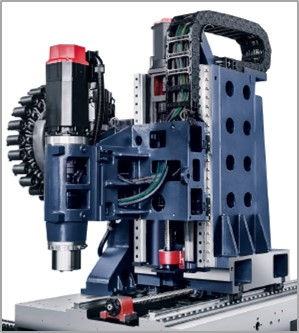

Column Moving-Type Machining Center

Highly efficient long spindle machining center that allows unmanned machining once long workpieces or various other parts have been set on it. ATC-installed column feeding structure significantly reduces non-cutting time.

High-Precision & High-Performance Feed System

The servo motor is coupled directly to the Y and Z axes, minimizing backlash during the feed. Eight bearings are applied to each of the X, Y, and Z support axes in rows of four, significantly increasing rigidity and bearing life.

Roller LM Guide & Linear Scale

The class-leading high performance guide ways on all axes enable rapid feeding and stable axis movement during hard cutting. Greater wear resistance than ball guides translates to precision feeding and longer machine life. Also, the linear scale as standard on the X-axis minimizes errors caused by thermal displacement.

User-Centric Control Panel

By allowing the control panel to move along the X-axis, the operator can use the control panel conveniently from any position. The control panel is ergonomically designed to maximize user convenience and efficiency.

Mechanical specifications

| Axis Stroke (X/Y/Z) [mm] | 4,000/520/570 |

|---|---|

| Distance From Table Surface To Spindle Gauge Line [mm] | 150 – 720 |

| Distance Between Columns To Spindle Center [mm] | 660 |

| Working Surface [mm] | 550×4500 |

| Max. Loading Capacity [kg] | 4,300 |

| Tool Storage Capacity [Amount] | 24 |

| Spindle Motor Power [kW] | 15/11 |

| Max. Spindle Speed [rpm] | 10,000 |

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Machining Centers

A600

- Vertical CNC Machining Centers

L1 / L2

- Vertical CNC Machining Centers

VESTA-610D

- Vertical CNC Machining Centers

VESTA-1300B