C1

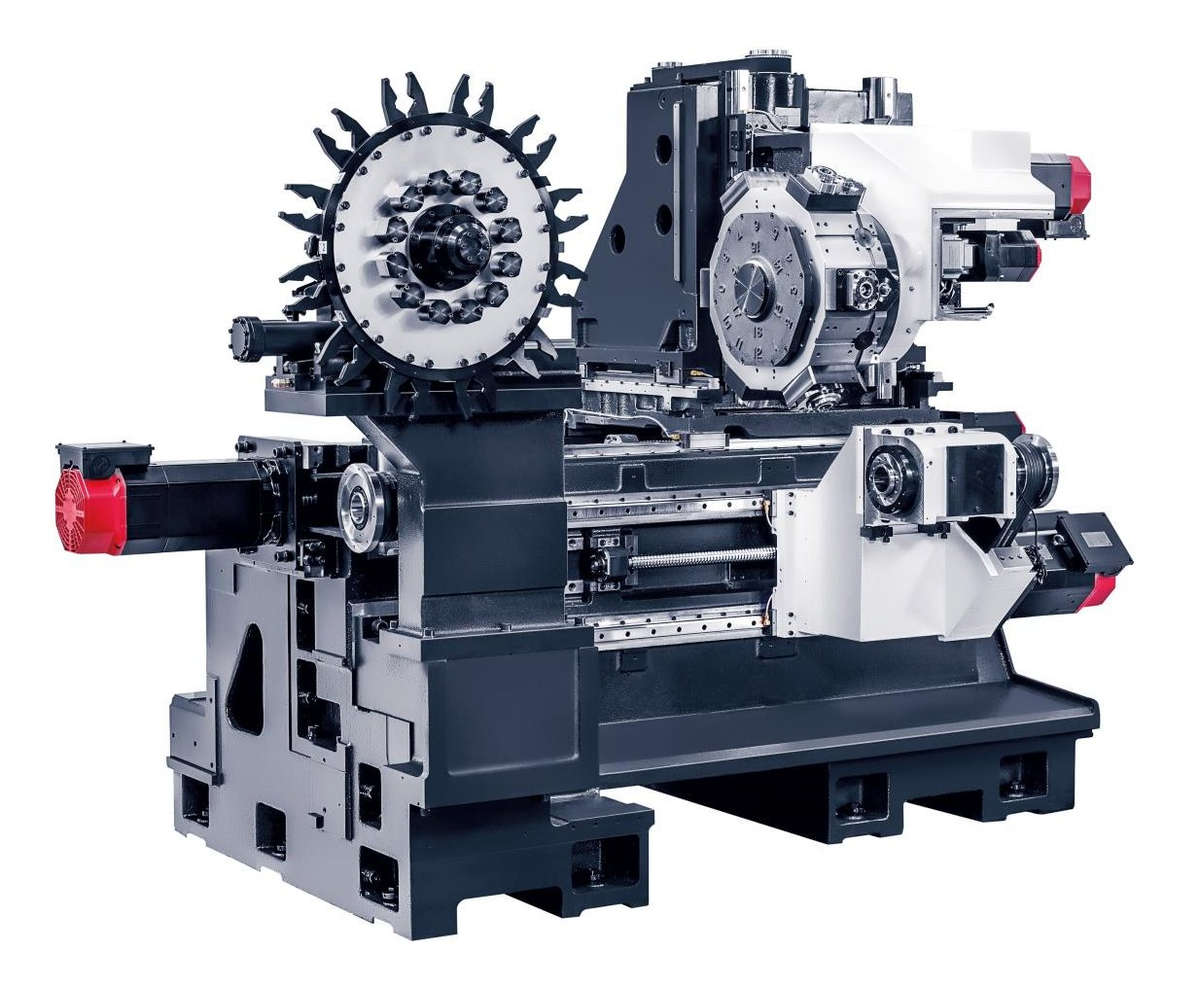

INTEGRATED HORIZONTAL TURNING CENTER

6″ Chuck With Tool Magazine & Y-Axis

C1 is an integrated multiplex turning center that combines processing capability of a turning center with the processing capability of a machining center obtainable through Y and C axis control. It can completely manufacture parts in complicated shapes in a single chucking operation.

Ideal for complex workpieces in small batches – for maximum flexibility. Thanks to its travelling column design, with its orthogonal X, Y and Z axes, the C1 unifies the machining characteristics of a lathe with the fabrication characteristics of a machining centre. This means that workpieces with complex contours can also be machined to an exceptional level of precision. At the same time, a sub spindle allows two machining steps to be carried out without clamping errors.

Additional tool magazine with 12 positions

The particularly robust 18-position turret (BMT-55 und C4) with driven tools does not have a sensitive spindle bearing, as is the case with turning and milling centres, and is therefore outstandingly well-suited to heavy cutting tasks, and carrying out such tasks with short cycle times. In addition, the machine has a 12-position wheel magazine with Capto-C4 holders which can be equipped with different tools during main time, so that all turning and milling tasks can be carried out in one operation, without interruption. Whilst a process is still running, and machining is still underway, the machine can thus be set up for the next workpiece.

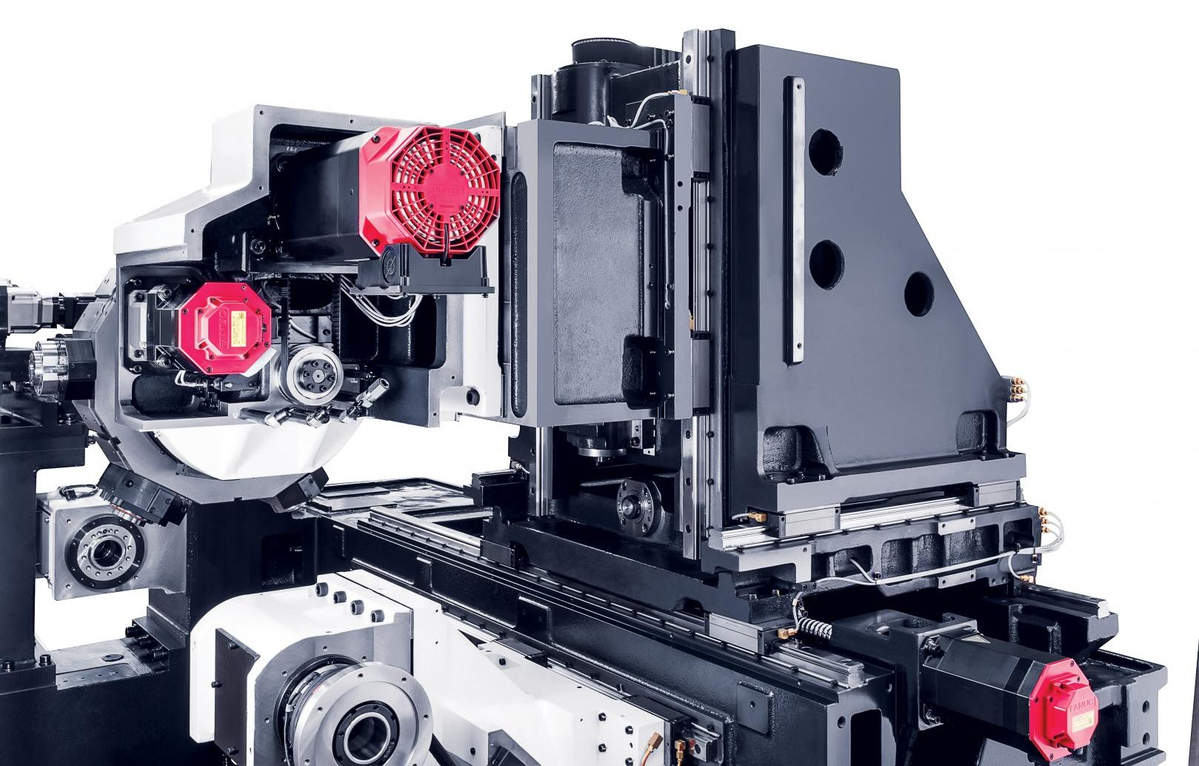

High rigidity linear rolling guideways permit rapid traverse speeds, dynamic machining and reduce non-productive time. Due to the high quality of the components used and the thermal stability of the new turning centre, high precision is ensured even during high-speed processes carried out in round-the-clock operation.

Orthogonal Y-axis

Independent orthogonal structure of X, Y, and Z-axes reduces feed error to zero, sustaining high rigidity and high precision even during prolonged processing.

Magazine

The magazine can be mounted with various tools and holders, enabling multiple turning and milling processes in a single, uninterrupted operation.

High Precision, High Rigidity Turret

Mounted with up to 18 tools, the turret enables faster and more stable machining through multiplex operations.

Mechanical specifications

| Swing Over Bed [mm] | Ø730 |

|---|---|

| Max. Cutting Diameter [mm] | Ø530 |

| Max. Cutting Length [mm] | 599 |

| Chuck Size [mm] | 6″ |

| Max. Spindle Speed [rpm] | 6,000 |

| Through Spindle Hole Dia [mm] | Ø62 |

| Spindle Motor (Upper / Lower) [KW] | 11/7.5 |

| Number of Tool Station [ea] | 18 |

| Rapid Speed (X/Z/Y/B) [m/min] | 30/30/15/30 |

| Max. Stroke (X/Z/Y/B) [mm] | 310/700/±50/750 |

| Turn Mill Spindle Motor [kw] | 5.5/3.7 (7.5/5) |

| NC Controller | Fanuc 0i-TF |

Processing software

- L-HTLDHwacheon Spindle Displacement Control System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Turning Centers

CUTEX-180

- 5-AXIS CNC Machining Centers (Multi Tasking)

SIRIUS-2500 5AX

- Vertical CNC Machining Centers

SIRIUS-UZ

- Vertical CNC Machining Centers

VESTA-1000+