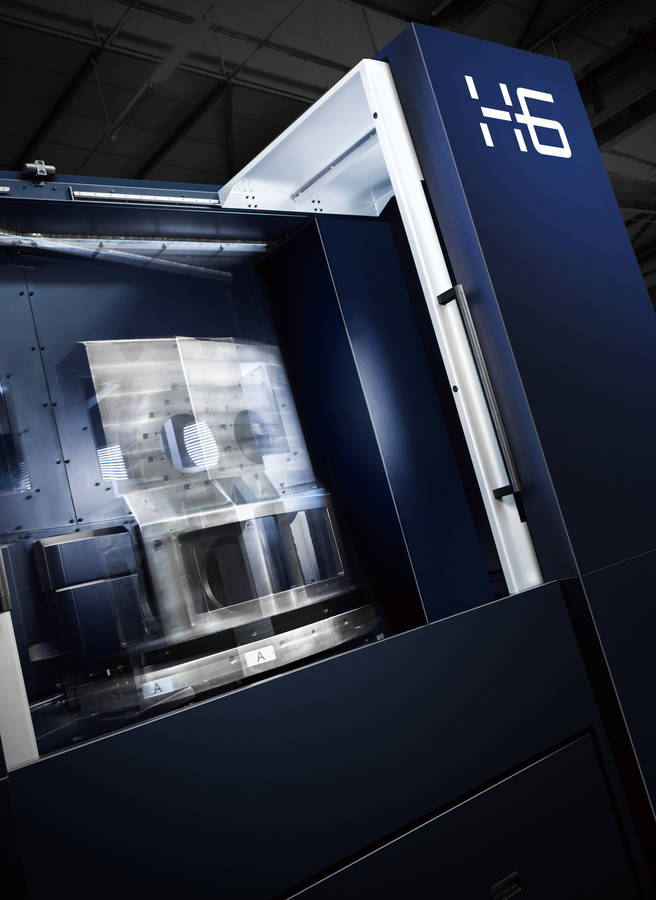

H6

HORIZONTAL MACHINING CENTER

With Pallet Size Of 630 MM And For Toughest Material

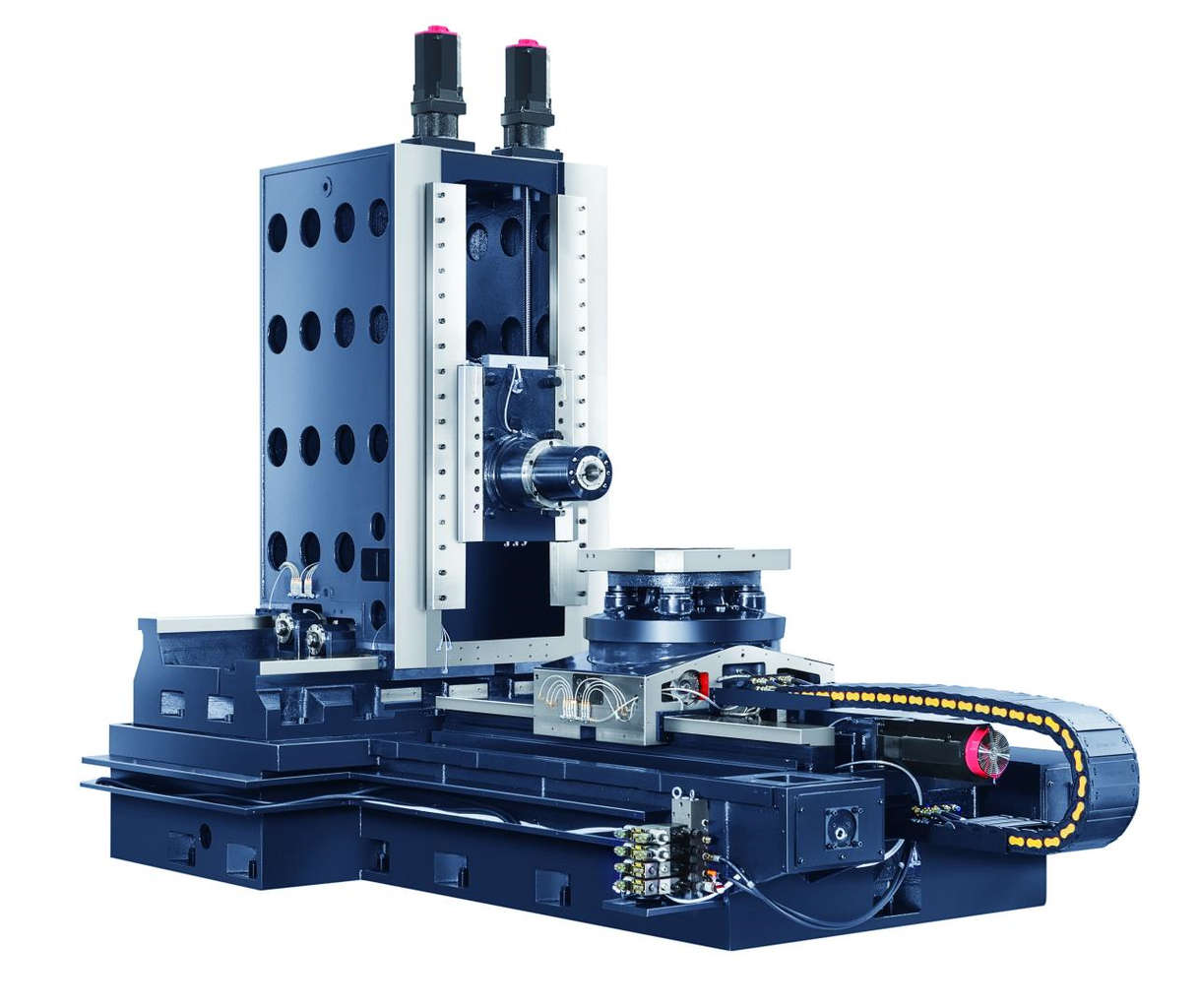

The H6 comes with two ballscrews and drives each on the X- and Y-axis. All linear axis are provided with extra wide box guide ways. This configuration makes the H6 an extreme powerful tool for heavy cutting and to machine materials such as inconnel and titanium.

- Twin-Drive in X and Y-axis

- Box-Way guides in all axis

- Hwacheon-Spindles:

Gear-driven spindle: 8,000 rpm (35/22 kW and 1654 Nm)

Built-In-Spindle with 12,000 rpm (30/25 kW and 420 Nm) - Pallet size : 630 mm x 630 mm (optional 630 mm x 800 mm)

Rigid And Precise Performance

H6 is a superb solution for production of various kinds of difficult materials and parts which require highest rigidity. The high rigidity with box way structure gives users extreme stable cutting conditions. Each twin drive system on X and Y axis ensures more precision and higher cutting rates. High torque spindle with strong gear drive and Hwacheon’s unique Oil-Jet cooling system ensures stable heavy-duty cutting performance at high quality even after long periods of machining. Additionally, stable and strong frame structure designed with 3D design and FEM analysis will enhance the quality of the work piece. H6 with Hwacheon’s unique software enables users to get highest efficiency, productivity, stability and convenience at the same time. High precision worm gear and rotary encoder will maintain the accuracy requirements at the CNC rotary table.

Tough, Rigid Frame Structure

Integral bed frame supports the drive system with highest stability, its thermally equal structure maintains geometrical accuracy.

High Precision Twin drive

High precision twin drive which is applied in X, Y axis ensures minimize yawing error during translational motion.

Gear Driven Spindle

The 2-speed auto-shift gear spindle delivers highest torque performance at extra low speeds; while providing excellent performance at high speeds.

Oil-Jet Cooling

The Oil-Jet cooling and the Jacket Cooling designs have been perfected by Hwacheon’s know how in building high quality spindles. Highly effective cooling systems minimize the thermal displacement during prolonged machine operations.

Machining Software

Hwacheon’s machining software monitors different variable parameters related to the work environment and machining conditions and adjusts for best quality results and optimum work efficiency in real time.

User Friendly Design, A Wide Range Of Optional Features

H6 offers user friendly design and a wide variety of options for enhanced applications, you can concentrate on what you do best: creating quality products-without losing your valuable time to the worries of machine failure and safety.

Mechanical specifications

| Stroke (X / Y / Z) [mm] | 1,050 / 900 / 1,000 |

|---|---|

| B-axis Rotation Angle | 360° |

| Working Surface [mm] | 630 x 630 |

| Table Loading Capacity [kg] | 1,600 |

| Max. Spindle Speed [rpm] | 8,000 |

| Spindle Motor [kW] | 35 / 22 (47 / 30) |

| Type of Tool Shank | BBT-50 (Opt.: CAT-50) |

| Tool Storage Capacity [Amount] | 40 (Opt.: 60, 90, 120, 150) |

| Weight [kg] | 26,500 |

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

- HRCCHwacheon Rotation Center Calibration System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Machining Centers

H8

- Horizontal CNC Machining Centers

A600

- Vertical CNC Machining Centers

SIRIUS-UL+

- Vertical CNC Machining Centers

VESTA-1050B