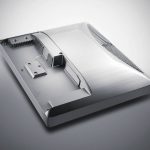

M2-5AX

5-AXIS UNIVERSAL MACHINING CENTRE

Optimal Solution For Machining Demanding Parts

Hwacheon M2-5AX can work on complex workpieces or mold & die applications which require different production processes with just a single setting. Coupled with the Hwacheon Total Solution, it is the ultra-precision 5-axis production solution you’ve been looking for.

Total Machining Solution

Hwacheon’s universal 5-axis center gives you the total machining solution – everything from tool selection to final product. The Machining Optimization system configures itself to fit your machining condition and application, to give you the best product result. The 2-axis rotary table with ø500 lets you create a product either in 5-axis processing methods. M2-5AX is built from 3D FEM analysis, and the software components specially created in-house by Hwacheon will increase the machine’s productivity and process speed.

High-performance spindle

The spindle integrates the motor to limit vibration, noise, and power loss at high speed rotation. The jet of oil is injected directly onto the spindle bearing for effective cooling, and the motor and the spindle assembly are jacket-cooled to limit the displacement caused by heat. To achieve greater precision, the spindle constantly monitors for possible thermal displacement and makes necessary adjustment in real time.

High-Precision Feed System (A/C)

The built-in, high-precision worm gear increases the servo motor’s torque, and application of the rotary encoder enables high-precision angle division and continuous rotation machining.

Mechanical specifications

| Axis Stroke (X/Y/Z) [mm] | 750 / 650 / 500 |

|---|---|

| Max. Angle of Rotary Axis (A / C) | 30 to -120 / 360° |

| Working Surface [mm] | Ø500 |

| Max. Table Load [kg] | 300 |

| Max. Spindle Speed [rpm] | 20 000 / 32 000 |

| Spindle Power (20k | 32k) [kW] | 22 / 18,5, 18,5 / 13 |

| Rapid Speed [m/min] | 50 / 50 / 50 |

| Tool Storage Capacity [ea] | 30 (BBT-40 / HSK-E40) |

| Machine Weight [kg] | 11 000 |

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

- HRCCHwacheon Rotation Center Calibration System

Learn more about Hwacheon processing software

Related products

- Horizontal CNC Turning Centers

CUTEX-180

- Horizontal CNC Machining Centers

A600

- Double Column Vertical CNC Machining Centers

SIRIUS-1750

- Vertical CNC Machining Centers

SIRIUS-UZ