M4-5AX

5-AXIS UNIVERSAL MACHINING CENTRE

Optimal Solution For Even Toughest Materials

For applications in tool, die and mould making, from precision components to heavy duty cutting, the M4 sets a new standard. Like no other machine in this segment, this machine stands out with its great weight, twin drives and extremely stable guideways. The M4 thus fulfils all the requirements of heavy duty cutting and is also suited to high cutting rates.

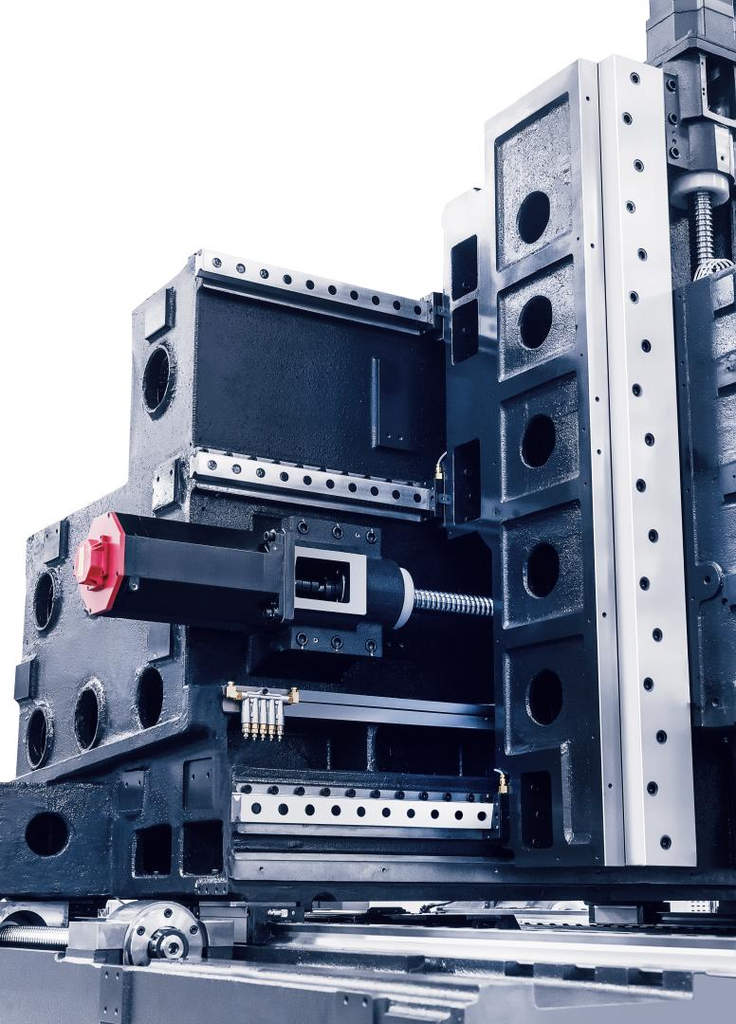

Heavy Meehanite Machine Bed & Powerful Drives – Made for Tough Cutting Conditions

M4-5AX is a 5-axis machining center that is specialized for machining molds and parts that have complex shapes and require highest precision. It is designed with a high-precision, high-rigid rotary table developed with Hwacheon’s technology. The high-rigidity, high-performance spindles and Hwacheon’s 5-axis software technology offer precise and fast machining environment, ensuring satisfactory results.

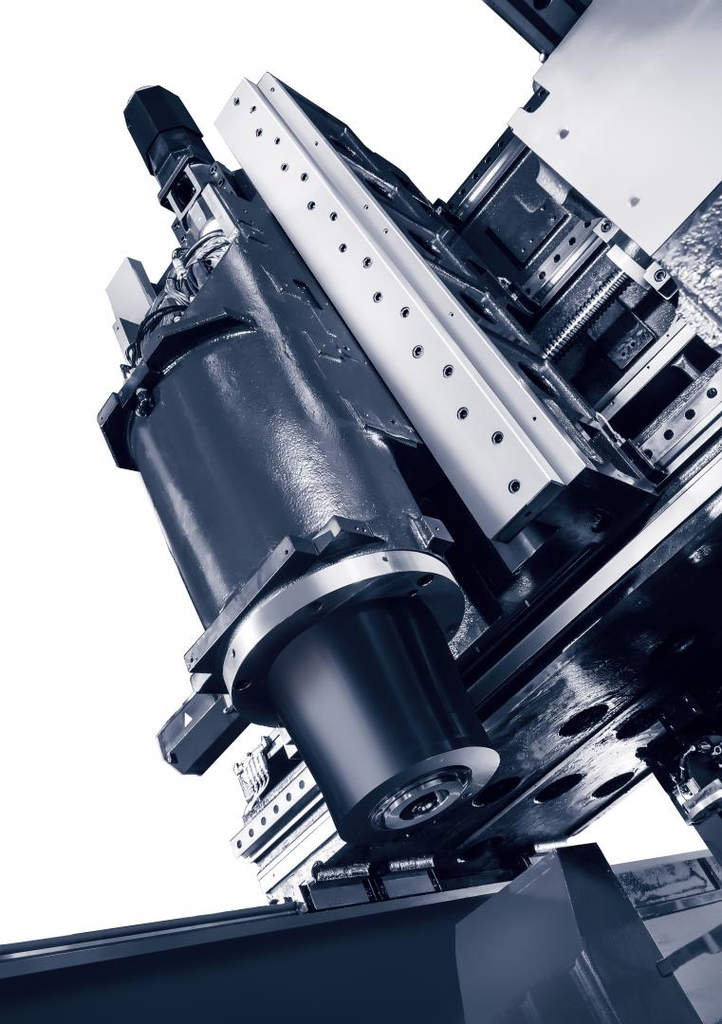

Various Spindle Series

- BBT-50 (OPT.: CAT-50, HSK-A100, SK-50)

- High-speed : 12,000 rpm

- High-torque : 8,000 rpm

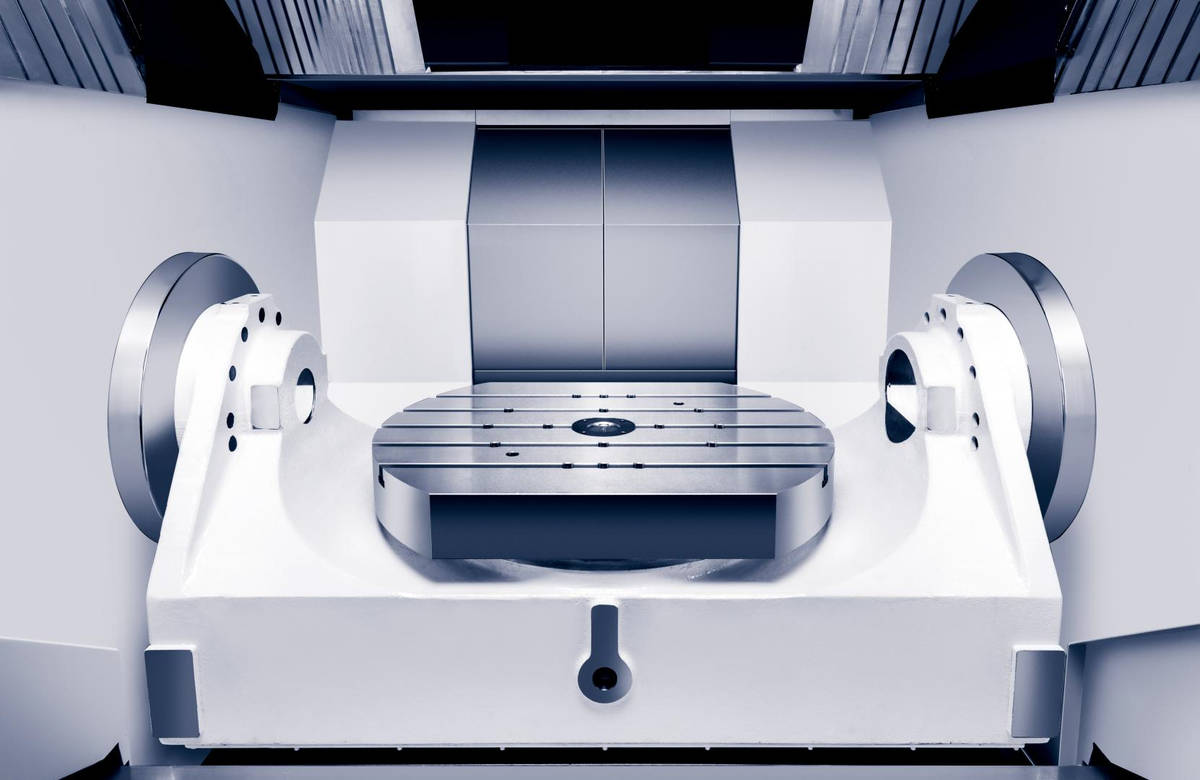

- High-precision Rotary Table

High-precision rotary encoder (controlled to the extent of 0.0001°)

- Loading of heavy weights : 1,200 kg

- Table size : Ø 800 x 630 mm

- Rapid speed (A/C-Axis): 20/30 rpm

- Maximum machining capacity : Ø 1,050

Work Convenience

- Excellent table accessibility

- Automatic open/close system for ceiling

- Effective discharge of chips and cutting oil

Mechanical specifications

| Stroke(X/Y/Z) [mm] | 950/1000/650 |

|---|---|

| Rotation Angle (A-axis/ C-axis) [deg] | 120/360 |

| Rapid Speed (X/Y/Z) [m/min] | 36/36/30 |

| Rapid Speed (A/C) [rpm] | 20/30 |

| Table Size [mm] | 800×630 |

| Table Loading Capacity [kg] | 1200 |

| Max Spindle Speed [rpm] | 12,000/8,000 |

| Type of Tool Shank | MAS-403 BBT-50 (OPT.:CAT-50, HSK-A100, SK-50) |

| Tool Storage Capacity [ea] | 30 (OPT.:60) |

| Floor Space (L x W) [mm] | 4210 x 5200 |

| NC Controller | Fanuc 31i-B5 |

Processing software

- HSDCHwacheon Spindle Displacement Control System

- HFDCHwacheon Frame Displacement Control System

- HTDCHwacheon Thermal Displacement Control System

- HTLDHwacheon Tool Load Detect

- OPTIMACutting Feed Optimization System

- HECCHwacheon Efficient Contour Control System

- HRCCHwacheon Rotation Center Calibration System

- HRCC-IIHwacheon Real-Time Geometric Compensation System

Learn more about Hwacheon processing software

Related products

- 5-AXIS CNC Machining Centers (Multi Tasking)

SIRIUS-2500 5AX

- Vertical CNC Machining Centers

HiREX-4000

- Vertical CNC Machining Centers

SIRIUS-7040 / 7050

- Vertical CNC Machining Centers

VESTA-1000+